Goggles Performance Specification

1. Introduction

Rugby Union is a full contact sport which requires any equipment used by players to minimize the risk of injury to both themselves and those playing with and against them. Rugby Goggles have been developed to ensure that people who require corrective lenses to play and who cannot or do not wish to wear contact lenses can do so. While Rugby Goggles are not intended to be protective, they may be used if considered so by people with reduced sight in one or both eyes. There may be occasions where wearing the Rugby goggle increases the risk of injury. Anyone intending to use Rugby Goggles while playing contact Rugby should consult with an ophthalmic specialist to get advice on whether they are suitable for them to partake in a full contact sport.

To ensure that Rugby Goggles minimize the risk of injury to wearers and other players, World Rugby has developed this Rugby Goggles Performance Specification (the specification). This specification is a rigorous test program that describes and assesses the physical and optical aspects of the goggle performance and design. In accordance with World Rugby Regulation 12 any goggles used for contact Rugby (at all levels of the game) shall comply with World Rugby Regulation 12.

Rugby Goggles are not intended to be protective, but it is recognized that in complying with the specification there is a likelihood that some protective qualities will exist. World Rugby have attempted to balance the risks to all players that may be introduced by the use of goggles with the need to enable their use. It is also recognized that the goggles will not be appropriate for those who need to wear corrective lenses but who cannot or choose not to wear contact lenses.

Compliance with this specification shall be completed by a relevant World Rugby Accredited Test House. All goggles meeting the requirements of the specification will be permitted to display the World Rugby Approved logo and only products displaying this logo will be permitted for use for contact Rugby games in all jurisdictions.

2. Terminology

For the avoidance of doubt, the following are definitions for terminology used in this performance specification. These may not be consistent with those used in the referenced documents (or in ISO 4007) and care should be taken when referencing to any external document.

Goggles - The entire appliance, composed of the visor, the padding the strap and the prescription insert, where used.

Visor - The main body of the goggle

Prescription insert - The part of the goggles, not included in the visor, containing the ophthalmic prescription of the wearer

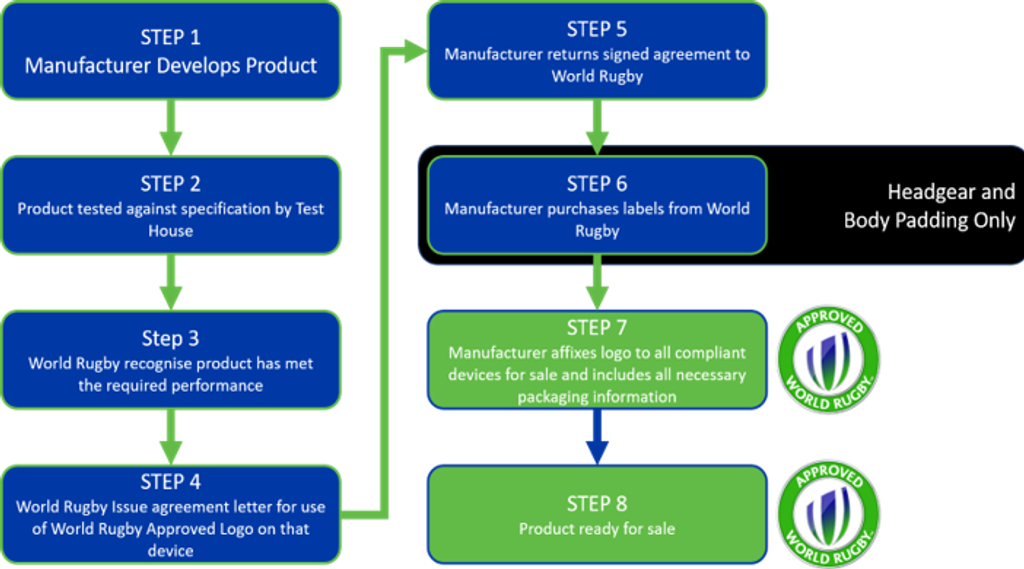

3. The World Rugby Process to Achieve Device Approval

4. Manufacturers

It is the manufacturer’s responsibility to ensure that any product being sold or supplied for use in rugby has been previously tested in the laboratory by an accredited World Rugby Test House to ensure it meets the requirements set out in this specification.

The manufacturer should consult with a Test House to ensure that the correct components are submitted to enable the test to be carried out in accordance with this specification.

The minimum sizes and numbers of samples provided for testing shall be in compliance with this performance specification.

Once all laboratory testing has been completed an application to use the World Rugby Approved Mark shall be sought from World Rugby and all devices shall display the approved logo at all times to be authorized for use (see Section 3 for an overview).

5. Test House Requirements

Test Institutes shall be independent testing establishments who have been accredited by World Rugby and have entered into a contract with World Rugby to provide these services.

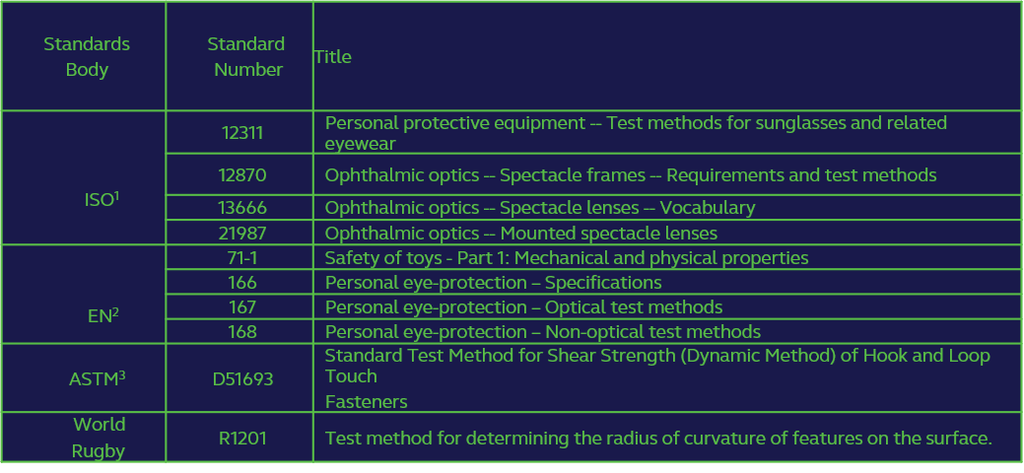

Test Institutes should be ISO 1702513 Accredited for all test procedures referenced in this document and must be ISO 17025 Accredited for all of those listed in the table below.

Further information about testing and accrediting test houses can be obtained at world.rugby/the-game/player-welfare/equipment/ath or from info@worldrugby.org.

6. Head-forms and Sizing

6.1 Head-forms

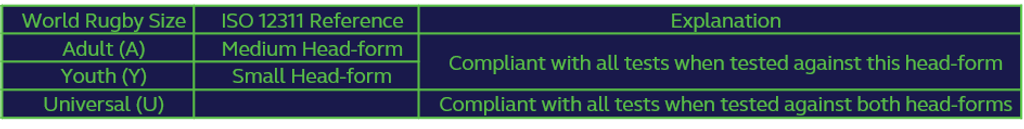

There are two sizes of reference head-form for all tests requiring head-forms within this performance specification as described in ISO 12311[1]. ISO 12311 also describes what head-form material shall be used for each particular test.

It is possible for a device to carry more than one size indication, if both are achieved then the U size indication shall be used. Where goggles are designed to be compliant against both head-forms then all testing shall be completed and reported separately for each head-form.

6.2 Sizing

Table 2 below indicates the sizing nomenclature that shall be used by manufacturers on World Rugby approved devices.

7. Physical Testing Requirements

7.1 Ergonomics

Goggles shall be designed and constructed so that all normal playing movements can be carried out without hindrance or discomfort. Goggles shall be free from projections, sharp edges or other defects which are likely to cause discomfort or injury to the wearer or any other players during use. The goggles shall be designed so that they can be worn comfortably with and without padded headgear.

7.2 Construction Materials

It is the manufacturer’s responsibility that all materials used should not be adversely affected by water, dirt, perspiration, toiletries, household soaps, or detergents. Products should conform to ISO 15487[2] and ISO 22958[3]. All materials coming into contact with the wearer’s body will not be of the type known to cause skin disorders and shall not cause abrasion of either the wearer or other players.

Materials coming into contact with the wearer's face or skin, except replaceable padding, should not undergo significant loss of strength or flexibility, or other physical change as a result of perspiration, oil, or grease from the wearer's skin and hair.

7.3 Padding Materials

Any padding materials used in the manufacture of the goggles should be for the purpose of reducing the risk of injury due to wearing the goggles and not from impacts experienced during the general course of play. Padding materials should be waterproof and allow for regular cleaning without becoming unfit for purpose.

7.4 Finish

All edges shall be smooth and rounded. The goggles shall incorporate curves that do not provide the potential to cut a player coming in contact with them. This shall be tested as per EN 71-1[4]. Goggles should be free from any significant defects likely to impair vision in use, such as bubbles, scratches, inclusions, dull spots, pitting, mould marks, scouring, grains, pocking, scaling and undulations. These defects shall be tested for using the method described in EN 167 (Clause 5).

8. Design

8.1 Zone of Coverage

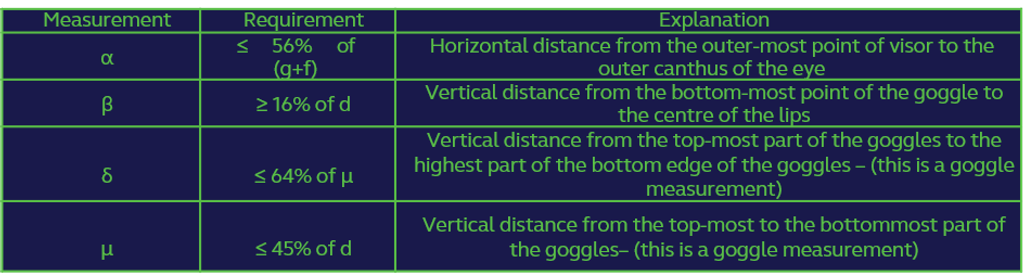

The goggles should be just large enough to achieve the optical performance required of them. The requirements listed in Table 1 (with dimension references from Figure 1) shall be met by the goggles using whichever head form (see Section 6) the goggles have been designated to be assessed against. Measurements α and β shall be taken when the goggles are positioned so that the centre of both eyes is located at a point µ/2mm (±2mm) from the uppermost part of the goggles and the horizontal centre of the goggles is l/2 (±2mm) from the centre of each eye. Distance references from Figure 1 shall be taken from EN 167[5] (Section 17) for the appropriate head form.

Note: The nose should be left exposed as much as possible. This is achieved by the limits set out for μ and δ.

8.2 Shape

The goggles should be designed so that the external surface is a continuous curve (in all directions) but not necessarily with the same radius of curvature. To align with the curvature of the head, the horizontal radius of curvature of the goggle should be between 70-90mm. These measures should be taken from the back surface of the visor. No feature on the outward surface of the goggles (that which an opponent may reasonably be expected to come into contact with) shall have a radius of curvature less than 12mm as tested using the method described in Appendix B.

8.3 Retention System

The retention system should be attached so that the goggles remain in their normal position during play. If a strap is used, it should be affixed to both sides of the goggles and pass around the back of the wearer’s head.

The release mechanism should be tested in accordance with the methodology set out in ASTM D51693vi. The resulting length-wise Shear Strength shall lie between .035 MPa and 1.03 MPa.

Note: All aspects of the retention system shall comply with the requirements of World Rugby Law 4.4 (c)vii.

8.4 Ventilation

It is the manufacturer’s responsibility to provide for adequate ventilation in the goggle design.

8.5 Force Distribution

The goggles should be designed to distribute forces around the wearer’s face where the supraorbital and zygomatic bones should offer the support.

9. Performance

9.1 Resistance to Fogging

Goggles shall remain free from fogging for a minimum of 30 seconds when tested in accordance with EN 168viii Clause 16.

Note: this procedure does not assess resistance to fogging of the complete device.

9.2 Protection against High Speed Particles

Goggles shall withstand the impact of a 6mm nominal diameter steel ball with a mass of 0.86g, striking the visor at a speed of 120m/s. In addition, the goggles shall withstand the impact of a 22mm nominal diameter steel ball with a mass of 43g striking the prescription insert at a speed of 5.1m/s. The tests shall be performed on the goggles assembled as intended to be worn using the method described in EN 168 (Clause 9 excluding Clause 9.2.2) and the indicated defects shall not occur. In addition, for goggles that constitute more than one piece, failure shall also be deemed to have occurred if the component parts become separated.

10. Optical test requirements

10.1 Applicability

The goggles should have the capacity to incorporate refractive correction. With present-day design constraints, it is envisaged this will normally comprise a prescription insert set behind the visor. In the event that goggles are created where there is not a separable prescription insert, the same specifications related to the prescription insert below apply to the prescription portion of the goggle. All references to an insert below shall be considered to apply to an insert and/or the prescription portion of the goggle.

Where applicable ISO 13666ix should be used as a reference for the definitions of the terms below.

10.2 Field of vision

10.2.1 Rationale

The visual angles stated are based on scrutiny of existing standards for personal eye protection6 and ski goggles7 and consultation with others from other sports including squash and racquetball8. This is balanced against knowledge of the limitation of the size of the prescription insert behind a visor of the curvature stipulated by the physical requirements of the goggle (Section 2.c), and knowledge of the literature on the field of view required for navigating a visual environment without compromise9.

The parameters below should be tested in accordance with EN 168 Clause 18.

10.2.2 Visor

The visor should have a large and unrestricted field of vision4. Ideally, all dimensions of field of vision should be as large as possible, but for a moving sport, the temporal and inferior fields of vision are particularly important.

The minimum field of vision of the visor shall be 45° superiorly, 60° inferiorly, 45° nasally and 80° temporally. It is recommended that the temporal field of vision should be at least 90°.

10.2.3 Prescription insert

The prescription insert shall provide the following minimum field of vision parameters: 35° superiorly, 40° inferiorly, 35° nasally and 40° temporally. This should be considered in conjunction with ocular centration distance2.

10.3 Curvature

10.3.1 Visor

The combination of physical requirements of the goggle and large field of vision require the goggle visor to align with the curvature of the head. As stated in the physical requirements section, the (as worn) horizontal radius of curvature of the visor should be 70-90mm. The vertical curvature is constrained only by the requirements of Section 8 above.

10.3.2 Prescription insert

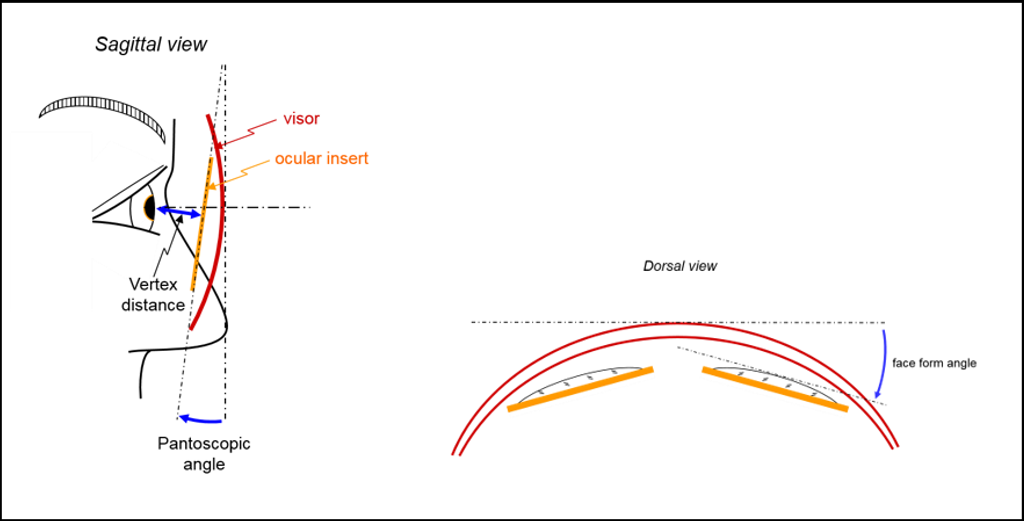

In common with average fitting for ophthalmic lenses, the recommended face form angle of the insert, as defined in ISO 13666, should be 10-15° and shall not exceed 18° (see Figure 2).

This measure should be tested with the visor and optical insert (with plano-powered lenses) placed on the appropriate head-form (Section 6).

10.4 Fit

Both measures below should be tested with the visor and optical insert (with plano-powered lenses) placed on the appropriate head-form (Section 6).

10.4.1 Pantoscopic angle

In common with average fitting for ophthalmic lenses, the as-worn pantoscopic angle, as defined in ISO 13666, of the prescription insert shall be 10º ± 2º (see Figure 2).

10.4.2 Vertex distance

In common with average fitting for ophthalmic lenses, the vertex distance, as defined in ISO 21987x, of the lenses should be no more than 15mm from the corneal apex (see Figure 2).

10.5 Refractive Power

10.5.1 Visor

The visor shall comply with the permissible tolerances for visors without corrective effect as detailed in Table 2 of EN 166xi and be measured using the method defined in EN 167 (Clause 3).

10.5.2 Prescription insert

In accordance with ISO 12870, the insert shall have the capacity to be glazed with ophthalmic lenses. The refractive power tolerances and other characteristics of prescription lenses are described in ISO 21987.

10.6 Size

10.6.1 Visor

The size of the visor shall comply with the physical requirements described in Section 7, and the field of vision requirements described in Section 10.1. The visor shall be of an adequate size to enable the prescription insert properties for which it has been designed to be achieved.

10.6.2 Prescription insert

The size of the insert should ensure that there is a sufficient field of vision for the wearer. Given that there is a known range of pupil centration distances in the population, this may mean that a different sized insert is necessary to facilitate larger and smaller centration distances. The respective median pupil centration distance can be found for each head form in ISO 12311. The distance between centres for the prescription insert should be sufficient to reasonably align with these values, such that the pupil of the eye is not dramatically decentred in the insert, as this would impact on the field of vision for the wearer.

This measure will be assessed in conjunction with the field of vision requirements in Section 10.1 with the goggle and insert (with plano-powered lenses) placed on the appropriate test head-form (Section 6).

10.7 Transmittance

10.7.1 Purpose

Goggles shall be free from tinting to ensure the wearer gains no advantage over Players not wearing goggles in various lighting situations.

10.7.2 Visor

The optical transmittance shall comply with luminous transmittance category 0.

10.7.3 Prescription insert

The manufacturer should provide guidance for dispensing the individual’s refractive prescription in terms of compliance with luminous transmittance category 0.

Transmittance shall be tested in accordance with the method described in EN 167 (Clause 6).

10.8 Material

10.8.1 Visor:

The material and thickness of the visor should be selected to ensure that there is minimal risk that a compressive force will cause the visor to either temporarily or permanently flex inwards (towards the wearer’s face) during the general course of play. It is suggested that the minimum thickness of the visor material should be 2mm [4].

10.8.2 Prescription insert

The material of the insert should be appropriate to mount and glaze ophthalmic prescription lenses. To minimise the ring scotoma created by the rim of the insert in the field of vision (as described in Section 10.2), the rim of the insert should be as thin as possible and should be made with a clear transparent material. However, the rim shall also have sufficient thickness and mechanical strength to securely mount prescription lenses. This mechanical strength is tested as part of the testing required by Section 9.2

Manufacturers should provide guidance about the material of the ophthalmic lenses and rim material to eye care professionals (ECPs).

4 ± 1 mm

11. Summary of guidance that Manufacturers shall supply

The information below shall be provided by the manufacturer within the packaging provided for all goggles issued to customers to provide sufficient information to Eyecare Professionals (ECPs) when dispensing the Player’s prescription.

11.1 Details of the purpose of the goggle and performance characteristics

The manufacturer shall indicate that the intended purpose of the goggle is to offer means to wear refractive correction for the sport of Rugby and describe the performance characteristics of the goggle.

11.2 Description of size of visor and insert parameters

- The manufacturer shall state the visor size and the recommended head size for their

- The manufacturer shall state the boxed centre distance of the insert, in the form of horizontal length and distance between

- The manufacturer shall state the size of the goggles in accordance with Table 1

11.3 Description of recommendations for ECPs dispensing this goggle.

The manufacturer shall supply detailed ophthalmic dispensing guidance to ECPs. Some key considerations have been summarised in Appendix A. A copy of this document will be supplied for all compliant products to be included in the packaging of all products.

The manufacturer shall describe the importance of consideration of optical centration, vertex distance and face- form angle of the insert. The manufacturer shall note that prescription compensation may be necessary for high ametropic prescriptions. This could include commentary such as:

“The curvature of the goggle necessitates a larger than typical face-form angle for ophthalmic prescriptions. This may require prescription compensation to minimise potential prismatic effect, and off-axis errors for high ametropic prescriptions. The vertex distance is stipulated at a maximum of 15mm for the test head-form, but it is recognised that the ECP will have to facilitate an individual’s measurements.”

11.4 Recommendations for appropriate lens materials

The manufacturer shall indicate that ophthalmic lens material used for the insert shall have enhanced impact performance with a recognized safety material, for example polycarbonate or similar materials.

11.5 Instructions for insertion and removal of insert

The manufacturer shall provide detailed instructions on how to install and remove the prescription insert, where applicable, and indicate whether the prescription insert needs to be removed for cleaning. The manufacturer should provide information on the products that may or may not be used for cleaning purposes.

11.6 Description of minimum luminous transmittance for prescription insert

The manufacturer shall state that luminous transmittance shall comply with that stated in the performance specification (category 0) unless there is a known medical reason for another transmittance value to be dispensed and permission has been received from World Rugby and the appropriate Union for deviation from this requirement to be made.

11.7 Details of the manufacturer name, and country

The manufacturer shall state their company details.

12. References

- IS EN 71-1: Safety of toys – Part 1: Mechanical and Physical Properties

- EN 168: Personal eye protection: Non-optical test methods

- ASTM D5169: Test method for shear strength (dynamic method) of hook and loop touch fasteners

- Dictionary of Optometry and Visual Science. 7th ed. M Millodot. Oxford: Butterworth-Heinemann, 2008. ISBN 978-0702029585

- EN 166: Personal eye protection

- EN 174: Ski goggles for downhill skiing

- ISO WD Squash and racquetball optical requirements

- Hassan et al. Field of view for navigation. Vision Research 2006

- ISO 13666: Ophthalmic optics – spectacle lenses - vocabulary

- ISO 12870: Ophthalmic Optics. Spectacle frames. Requirements and test methods

- ISO 21987: Ophthalmic optics – mounted spectacle lenses

- ISO 8980-3: Ophthalmic optics - Uncut finished spectacle lenses Part 3: Transmittance specifications and test methods

- ISO 17025: General requirements for the competence of testing and calibration laboratories

All standards refer to the most recent publication date unless otherwise specified.

13. APPENDICES

13.1 Appendix A - Ophthalmic Dispensing Guidelines for Eye-Care Professionals (ECPs) for lenses to be mounted

Below is a list of suggested considerations to be provided by the manufacturer to ECPs. A document including these will be provided to manufacturers which shall be included in packaging of goggles. World Rugby may, with appropriate guidance, decide to adjust and/or add to this information without notification within this Performance Specification.

- Lens Material

For safety reasons, it is recommended that the lenses shall have enhanced impact performance with a recognized safety material, for example polycarbonate or similar material.

- Lens Form

In the case of plus lenses which are to be mounted in the prescription insert, flatter form aspheric designs should be considered to ensure sufficient clearance between the front surface of the lens and the rear surface of the visor. The shallower curve on the front surface of a minus lens normally provides sufficient clearance.

- Vertex Distance

The vertex distance should be no more than 15mm from the corneal apex.

- Face form angle

The recommended face-form angle of the insert is 10-15° and should not exceed 18°.

- Measurements

For dispensing the prescription insert, an up-to-date refractive prescription including vertex distance is necessary. Distance pupil centration distance should be measured.

- Prescription compensation

Prescription compensation should be considered for any change in vertex distance.

Prescription compensation should also be considered for larger face-form angles. This could be compensated for by two means:

- alteration of the prescription to take into consideration the astigmatic component induced by face-form angle to ensure the effective power of the lenses is appropriate for the individual; and/or

- consider decentring the lenses outwards to satisfy the centre of rotation condition in the horizontal meridian. Given that this will induce prismatic effect, the individual’s capacity to tolerate this should be carefully

13.2 Appendix B - Test method for determining the radius of curvature of features on the surface

APPARATUS

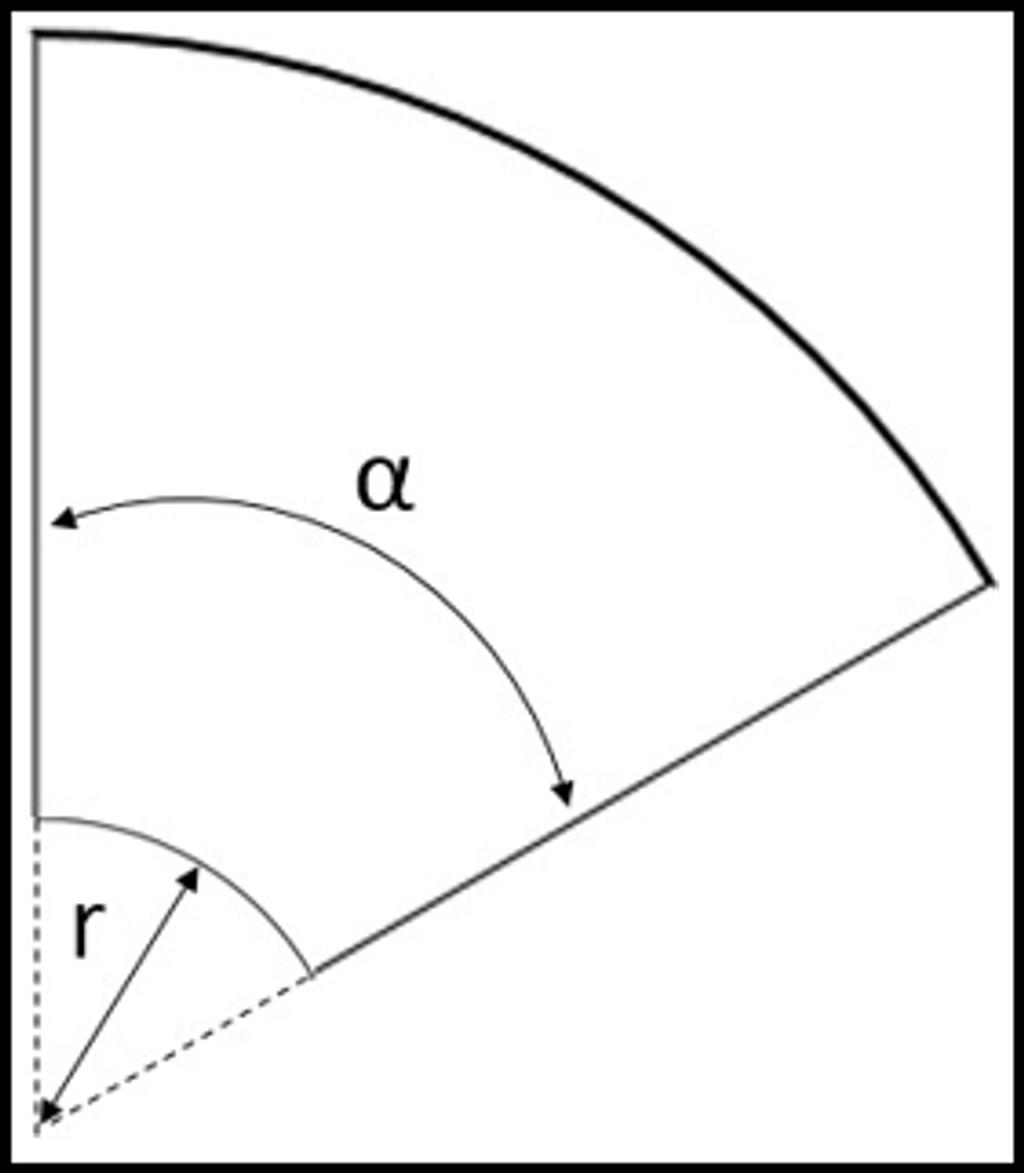

An appropriate radius gauge made of metal (steel or aluminium) and not more than 2mm thick shall be used. The shape of the gauge is shown in Figure B.1, where r shall be 12mm ±0.1mm and α shall be 60° ±2°.

Figure 1: Radius Gauge

PROCEDURE

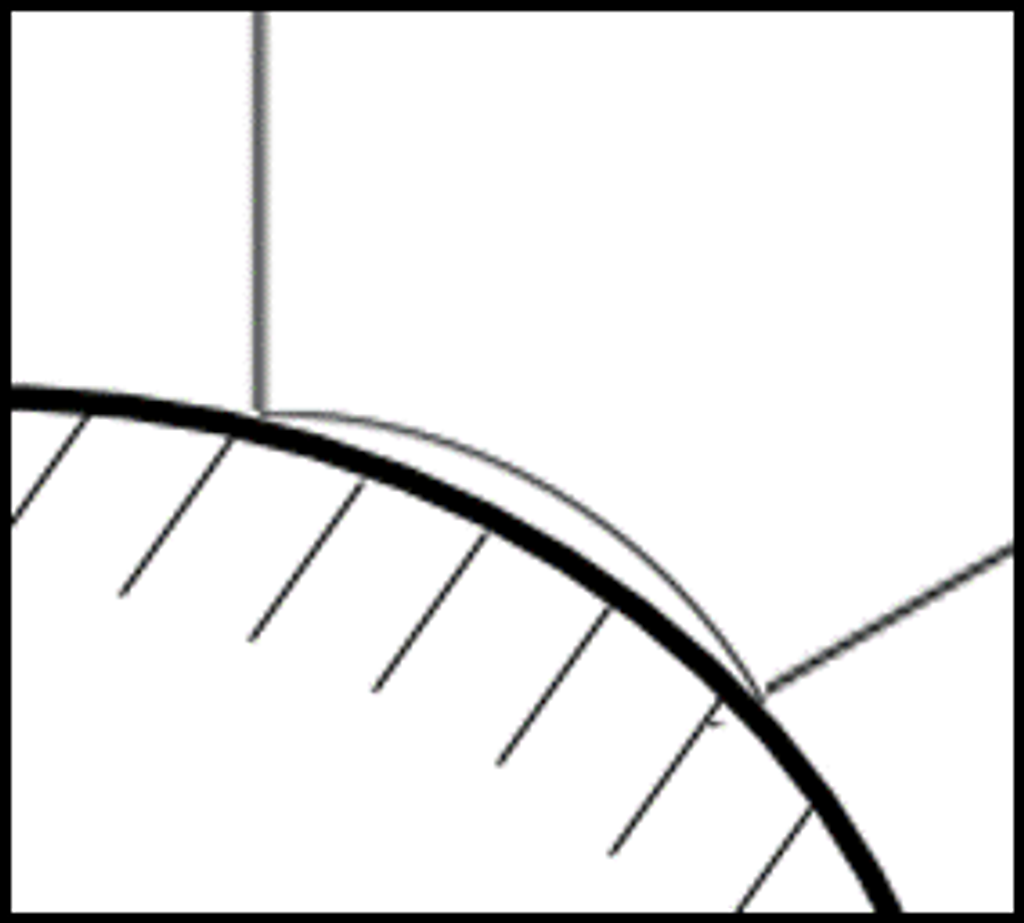

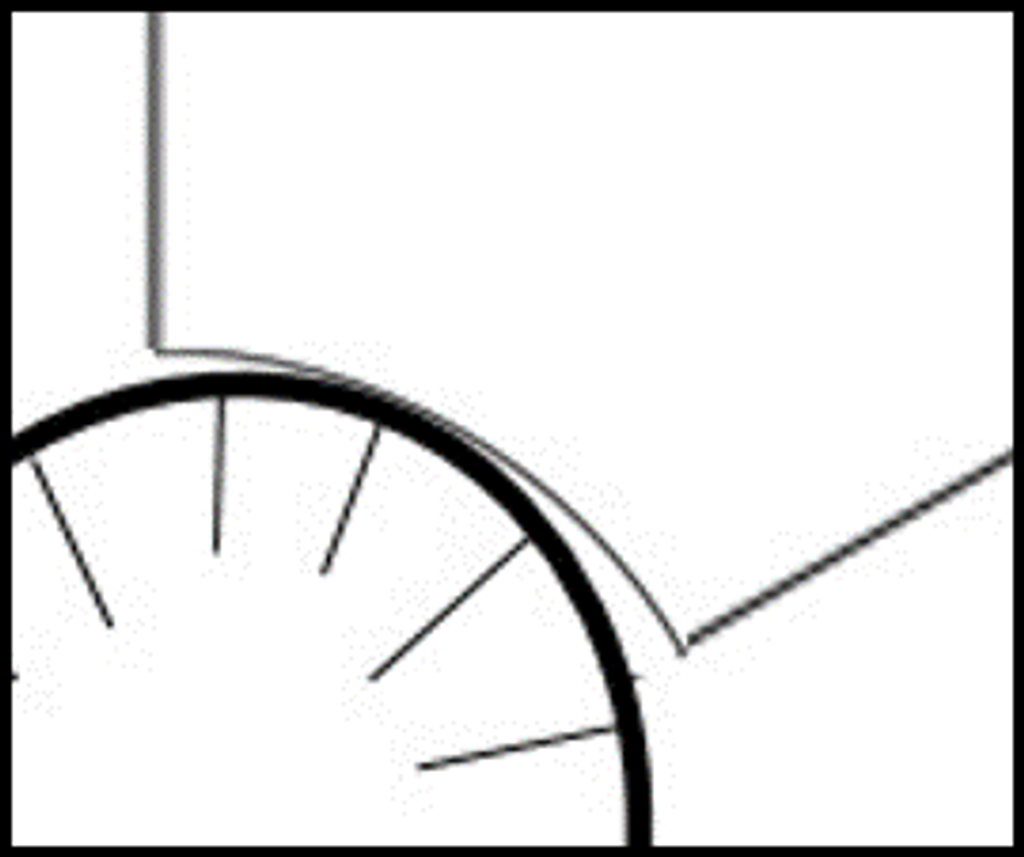

For all profiles of depth greater than 1mm ±0.1mm place the gauge in the areas of minimum radius of curvature of the area to be tested. If both ends of the gauge touch the surface of the Device, then that area passes the requirement. Figure B.2 illustrates the procedure and the pass and fail conditions.

Figure B.2(a): Pass Condition

Figure B.2(b): Fail Condition

14. Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this document, any party who makes use of any part of this document in the manufacture of rugby headgear (a "User") does so at its own risk and shall indemnify World Rugby their officers, directors, servants, consultants and agents against all claims, proceedings, actions, damages, costs, expenses and any other liabilities for loss or damage to any property, or injury or death to any person that may be made against or incurred by the World Rugby arising out of, or in connection with such User's use of this document.

Compliance with the requirements detailed in this document by a User does not of itself confer on that User immunity from legal obligations. Compliance with the requirements detailed in this document by a User constitutes acceptance of the terms of this disclaimer by that User.

World Rugby reserves the right to amend, update or delete sections of this manual at any time as deemed necessary. This World Rugby manual may not be reproduced in whole or in part in any manner without the permission of World Rugby.