Rugby Turf Performance Specification

1. Introduction

Rugby Union as a sport was quick to adopt new generation (3G) artificial grass surfaces for the development of the game. What is now referred to as World Rugby Regulation 22 was introduced in 2003 to ensure that 3G surfaces replicate the playing qualities of good quality natural grass. Regulation 22 defines those artificial grass systems specifically designed for the game of rugby union and as such are referred to as Rugby Turf. Climatic conditions, in many countries where the game is played, make it difficult to grow natural turf. In countries where Rugby Union is developing, Rugby Turf offers credible alternatives to those parts of the world where climate or resources make the growing and maintaining of good quality natural grass pitches difficult or impossible to achieve. In future it is hoped that the development of multi-sport artificial turfs, where Rugby Union and Association Football, amongst other sports, can be played, will provide a potential solution to facility operators wishing to maximise the use of their facilities through community use. Rugby Turf fields can be used significantly more intensely than natural turf fields, consequently where resources are limited, or space is limited it is a persuasive argument for consideration. Guidelines for natural turf can be found on www.worldrugby.org under Play Rugby or upon request from the World Rugby Technical Services Department.

To ensure that these new types of playing surfaces replicate the playing qualities of good quality natural grass, provide a playing environment that will not increase the risk of injury to players (current statistics indicate that there is no increased risk of injury) and are of sufficient durability (provided they are maintained), World Rugby has developed the Rugby Turf Performance Specification. Revised in 2011, 2012, 2015 and again in 2016 the Performance Specification is a rigorous testing programme for artificial turf that assesses the ball surface interaction, player surface interaction durability and environmental resistance of products and encourages the continuing improvement of Rugby Turf to meet the needs of the game. In accordance with World Rugby Regulation 22 any artificial turf used for any form of competitive contact rugby (at all levels of the game) needs to comply with World Rugby Regulation 22 and the Rugby Turf Performance Specification.

The laboratory test programme, which an artificial turf must satisfy as part of the Rugby Turf Performance Specification, includes a programme of simulated use to assess the ability of a surface to perform over a period of time. The degree of simulated use undertaken on a product is designed to replicate levels of use which are significantly greater than those achieved by natural turf systems. Potential installers of artificial turf fields should note, however, that experience has shown fields subjected to overuse will not be able to retain the demanding performance criteria of the Rugby Turf Performance Specification for the life of the playing surface. Manufacturers of Rugby Turf systems should be able to clearly advise on the weekly usage of these surfaces for rugby. Failure to undertake adequate maintenance will also reduce the period of time a field may satisfy the requirements of the Rugby Turf Performance Specification.

This edition of the manual supersedes previous editions with effect from June 1st 2020.

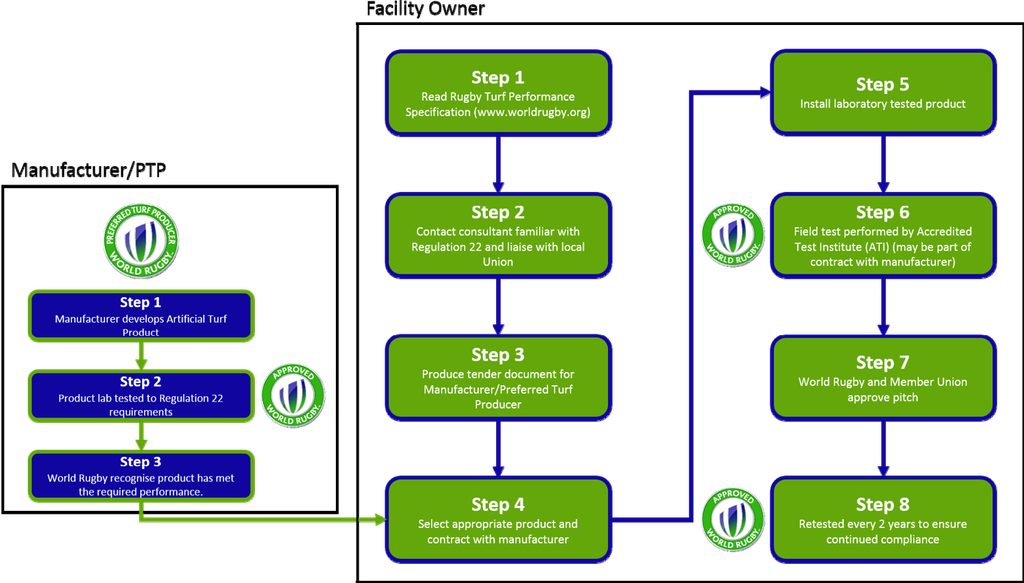

2. The World Rugby Process to Achieve Successful Field Certification

Unions, clubs or organisations seeking to install/use Rugby Turf must comply with the Rugby Turf Performance Specification.

3. Manufacturers

It is the manufacturer’s responsibility to ensure that any product being installed has been previously tested in the laboratory by an Accredited Test Institute (ATI) to ensure it meets the requirements set out in this specification.

The manufacturer should consult with an ATI to ensure that the correct components are submitted to enable the test to be carried out in accordance with this specification.

The minimum size of the samples provided for type testing must be in compliance with the performance specification.

Where UV testing has already been completed on a thinner yarn (dimensions are less than or equal to those of a yarn already tested) then UV testing is not required on the thicker yarn as long as the DSC results are within the applicable ranges.

Where simulated wear (Lisport XL) on a carpet with thicker yarn (dimensions are greater than or equal to those of yarns already tested) then simulated wear testing is not required where all other aspects of the product are the same.

Manufacturers must provide a product declaration to World Rugby before the product testing can be undertaken.

Prior to installation, manufacturers must be able to provide evidence (in the form of a World Rugby Product Test Certificate) that the product has been shown to comply with the product test requirements outlined in this Performance Specification to the client who is undertaking the installation and also to the Union which has jurisdiction over the venue.

World Rugby Preferred Turf Producers will be issued a certificate on verification from an ATI that a field is Regulation 22 compliant for fields that do not have the designation of “Suitable for training only”.

Note that it is not a requirement to be a PTP to achieve a Regulation 22 compliant field, any manufacturer can do so by fulfilling all of the requirements of this specification.

4. Test Institute Requirements

Testing for compliance with World Rugby Regulation 22 can only be undertaken by an Accredited Test Institute (ATI) and field testing can only be completed by an accredited technician.

Type of Accredited Test Institute

There are two distinct types of ATI:

- Product Testing ATI – the ATI is accredited to fully test artificial turf systems in the laboratory to determine if they [satisfy] comply with Step 4 (see above) of the field approval

- Surface Testing ATI – the ATI is accredited to fully test artificial turf fields to determine if they comply with World Rugby Regulation

Some ATI are both surface testing and product testing ATIs and other ATIs are surface testing ATIs only.

Requirements

- All ATIs must be independently owned entities with no legal links (save for service contracts) with any manufacturer or other industry-based

- ATI’s are required to demonstrate their capability of performing the tests required of Regulation This is partly completed by their achievement of ISO 17025 certification for all tests required.

- In addition to ISO accreditation, ATIs are required to have at least one accredited technician within their organisation. Accreditation is achieved via a Round Robin, organized by World Rugby in conjunction with FIFA to ensure that they can demonstrate

- All ATIs must have a current contract with World Rugby

Round Robins

- Product testing Round Robins are expected to take place every 2-3 years and will require ATIs to test given products and to submit the results to World Rugby for World Rugby reserves the right to have an independent representative on site while the testing is being completed should it be deemed necessary.

- Surface testing Round Robins will take place at least annually in a location decided upon by World Rugby, in conjunction with Further details on these prerequisites are available in the next section.

- The Round Robin Requirements are detailed separately from this specification and are available on request from World Rugby.

Equipment

ATIs must own their own equipment and have calibration certificates and any other requirements as set out in ISO 17025. Outsourcing of product testing is not permitted except in exceptional circumstances and only to a laboratory that is ISO 17025 accredited for that test and with acknowledged permission from World Rugby.

Accreditation Expiration

ATI accreditation must be renewed, by the signing of a new contract with World Rugby, every 2 years. ATI Accreditation will expire in instances where:

- They cease to be considered independent by World Rugby

- The ATI contract expires and no new contract is signed

- The ATI ceases to have an accredited technician employed/contracted.

- The terms of the contract are not met and the contract is invalidated

In instances where product testing ATIs cease to be accredited, they can, once the applicable requirements are met, continue to be a surface testing ATI.

Technician Accreditation

Accreditation is received once the technician has been confirmed as passing the Round Robin and their ATI has successfully completed the identification element of the process. Accreditation commences on the day after the Round Robin was completed. Once a technician becomes accredited this accreditation will cease to be valid under any of the following circumstances:

- The accreditation is not renewed within 5 years from the last Round Robin

- The technician’s affiliated test institute is no longer considered an ATI

- The technician fails to successfully complete a Round Robin – in this instance the technician will be given a one year to successfully complete a Round Robin, if this is not done then accreditation

- A technician becomes affiliated to another ATI

Technicians are permitted to reaccredit themselves at any time during the 5-year period, however subsequent reaccreditation must be completed within 5 years from the most recent successfully completed Round Robin.

Reaccrediting technicians who are completing the last possible Round Robin prior to their accreditation expiring will be considered as applicant technicians. Applicant technicians who do not complete the Round Robin successfully will not be considered accredited from the date that that Round Robin ends and will need to complete another Round Robin before they can become accredited.

5. Applicable Test Requirements

The requirements used to assess artificial turfs and installed fields are described in this Rugby Turf Performance Specification. Where a test method is given a dated reference, subsequent amendments to, or revisions of, the requirements will apply to this document only when incorporated into it by amendment or revision. For undated references, the latest edition of the publication referred to applies.

In general the applicability of this specification and others which have preceded it are:

- Products submitted for testing must comply with the performance specification in effect at the date of submission or more recent performance

- Fields installed must comply with the performance specification in effect at the date of installation. A transition period will be provided when changes to the Performance Specification are made as determined by World Rugby.

In instances where a shock pad which was installed to comply with a previous version of the Performance Specification is to be used, then the combination of new carpet and old shock pad should be treated as a new product and must comply fully with this latest version of the specification. The laboratory tests can be completed using a new sample of the same shock pad but the shock pad on site must comply with the requirements set out in Section 9 below. Furthermore, it is the sole responsibility of the manufacturer to ensure when re-using and existing shock pad that the combination with a new turf complies with the Regulation 22 field requirements.

The uncertainty of the test method should not be taken into account to determine if the result passes or fails the requirements.

6. Retest Requirements

As detailed in World Rugby Regulation 22, all fields must be retested a maximum of two years from the date of the last test in order to maintain their status as Regulation 22 compliant. The following exceptions apply:

- Match and Training venues used at Rugby World Cup must have been successfully tested within three months of the start of the competition

- Match venues used In the Sevens world Series must have been successfully tested within three months of the first day of competition for that Series.

7. Product Test Requirements

7.1 General

Product Test Requirements are separated into 4 distinct groups:

- Performance Testing

- Quality Testing

- Identification Testing

- Construction Testing

Results should be recorded as accurately as the apparatus used allows, averages should be calculated to this number of decimal places or to one decimal place more than the permitted values are expressed in, whichever is the greater.

All white and yellow products used for markings (lines and logos where applicable) must be tested as if individual products. Additional colours used for markings must be subjected to simulated wear and must achieve similar performance when compared to the green, white and yellow markings. These additional colours can be tested when tufted together as long as the area of each colour is no less than 0.2m x 2.5m and the stripe of colour is in the direction of manufacture The FIFA method for assessing this comparison should be used.

7.2 Sample provision

Samples must be provided in accordance with the advice of the Accredited Test Institute.

7.3 Laboratory Performance Testing

Performance testing is used to simulate how players and balls interact with the surface under different conditions. Details of the tests, test methods and requirements for product testing are available in Section 13.1.

Simulated Wear simulates the physical wear of the sample using the Lisport XL apparatus for 6,000 cycles plus additional conditioning cycles.

Products that differ only in that they contain a higher tuft rate per linear metre do not require separate tests on the Lisport XL for each combination. Note: this applies to the requirements in place for post-simulated wear only.

Systems that fail to meet the requirements when frozen (at -5°C) will require an underground heating system to comply with the Performance Specification if installed in countries where the temperature falls below freezing annually and must be designated as such, namely not suitable without an underground heating system.

7.4 Laboratory Quality Testing

The test requirements listed in Section 13.4 are intended to assess the quality of the product. Quality testing is used to ensure that the product complies with the requirements of tests which cannot be practically performed in situ and relate to the strength and resistance to wear of the product.

Where a test is indicated as aged, artificial weathering should be undertaken in accordance with EN 14836 (UVA) at 5,000 hours’ exposure time.

Notes on the Quality Testing Requirements:

- Where a local requirement exists, which exceeds the UVA exposure requirement of 5,000 hours, then local requirements shall supersede this requirement

- Where the water permeability requirement is not met, the product may still be used specifically for indoor use and on bases designed to be impermeable. Furthermore, World Rugby reserves the right to provide dispensation on a case by case basis to systems that are installed in specifically low rainfall areas of the world where the permeability requirement may be irrelevant

- Where the building materials used prevent the construction of a permeable sub-base the system should be designed to allow horizontal movement of rainwater to avoid the field In such circumstances, the tolerances permitted for the surface under a 3m straightedge should be reduced to ≤ 6mm.

Heat ratings are used to give an indication as to the suitability of the product for different climatic conditions and of the amount of splash that can be expected from the surface respectively.

7.5 Laboratory Identification Testing

Identification testing as detailed in Section 13.4 must be completed in the laboratory and on site. Identification testing is used to ensure that the product tested in the lab is the same as that installed on the field.

Where the pile height declared is less than 60mm, all of the following manufacturer’s declarations must be made:

- Total pile weight must not be less than 1,300g/m2 when tested to ISO 8543

- Stabilizing infill depth must not be less than 10mm.when tested to EN 1969

- Splash must not exceed 3.5% when tested to the appropriate FIFA Method

World Rugby strongly recommend that fields use a 60mm carpet as these have a proven track record for providing excellent surfaces for rugby. Consideration of carpets with pile heights between 50mm and 60mm should be restricted to multi-sport, community-based fields that wish to offer rugby as an additional or optional sport.

7.6 Use of Data from Previously Tested Artificial Turf – Resistance to Artificial Weathering

If an artificial turf product has been previously tested by a World Rugby Accredited Test Institute for resistance to artificial weathering the results may be used for the new product so long as it meets the requirements for:

- DSC

- Pile Characteristic (monofilament, fibrillated, etc)

- Pile thickness, and

- Colour

8. Surface Testing Requirements

World Rugby and the World Rugby Member Union or the client must receive evidence, from an Accredited Test Institute, that the system that is due to be installed has been successfully subjected to all the relevant laboratory testing and has met all requirements of such. The manufacturer/World Rugby Preferred Turf Producer must submit the relevant documentation to World Rugby and the World Rugby Member Union, in whose jurisdiction the field lies, or the client in advance of the installation.

Any product being installed must have been laboratory tested and be shown to comply with Regulation 22 prior to the installation taking place.

Surface Testing Requirements are separated into four distinct groups:

- Performance Testing

- Laboratory Testing

- Visual Inspection

- Construction

The field shall be tested in the positions as specified in Section 8.6 below. Field tests should be carried out on areas of turf which do not contain seams, inlaid lines or painted on lines. Maintenance of the field shall not be undertaken during the field test therefore no brushing, levelling or topping up of infill should be carried out. Should a minor problem be identified during testing which can be resolved within 24 hours the World Rugby Accredited Test Institute may be commissioned to return to the field to complete the testing programme.

Weather conditions during the test should allow for the proper and correct performance of the test procedures which should not be hindered or altered by wind, rain or cold conditions. Testing will be conducted within the temperature range +5°C to +45°C (temperatures refer to the surface temperature of the infill materials). Wind speed should not be so great as to affect the testing process, namely a maximum of 2.0m/sec. Pitches must be re-tested within two years from the date of the last successful test.

The number of test areas on smaller pitches, e.g. training pitches, must be pro-rated by area using the 15 test points within the field of play, where six test points is the minimum number for any field.

Results should be recorded as accurately as the apparatus used allows, averages should be calculated to this number of decimal places or to one decimal place more than the permitted values are expressed in, whichever is the greater.

In the event that an ATI becomes aware of any issues relating to testing, performance or compliance of a playing surface they must immediately report the issue to World Rugby.

In instances where there are safety or quality concerns that may affect the suitability of the field to be used for rugby, World Rugby reserve the right to include any laboratory-based test that is not normally conducted on the field or any other additional test that it deems appropriate to assess the field’s suitability or otherwise.

8.1 Surface Performance Testing

The tests, test methods and required limits that must be achieved for a surface to be considered Regulation 22 compliant are detailed in Section 13.1.

Variance is the maximum variation that is permitted between the average reading for all locations and that of any individual location assuming all results are within the required limits.

In instances where World Rugby deem it appropriate the following tests can be included in the surface performance testing:

- Ball Roll

- Skin/surface Friction

- Skin Abrasion.

8.2 Surface Identification Testing

Identification testing is completed at the initial test phase, on retest only those necessary identification tests are undertaken. Section 13.4 identifies the tests, test methods and required variations from the manufacturers’ declarations that must be completed on laboratory tests, initial field tests and on retests of fields respectively.

The samples of artificial turf shall be supplied to the laboratory when they undertake the field test. Samples of yarn, sand and rubber from the field shall be obtained by the laboratory. Samples should be submitted in adequate time so that if it is found they do not comply with the requirements of the World Rugby specification a new laboratory test using the new materials can be made prior to installation of the artificial turf and subsequent field test.

For Rugby Turf tests the above measurements shall be made in four different areas of the field not subjected to high areas of wear or usage.

For infill samples, a minimum sample of 250g shall be taken from the top portion of the performance infill on six of the test positions detailed in Diagram 8.1.

8.3 Surface Construction

The tests, test methods and requirements that must be completed for a surface to be considered Regulation 22 compliant are detailed in Section 13.3.

8.4 Surface Visual Inspection

Prior to, and during, the field test programme it is necessary to conduct a visual inspection of the surface to ensure that there are no significant defects in the surface which could be hazardous to players. Features including, but not limited to, the following should be noted:

- Seam failures of any type such as lumps of glue, incorrect stitch orientation and missing tuft lines

- Looped yarn/pile

- Delamination of the adhesive from the turf

- Free pile height

- Uneven fill - low or high areas

- Exposed irrigation heads

- Exposed goal and flag sockets

- Upright goals

- Position of goals

- Loose socket covers for goal sockets

- Loose or dangerous goal structures or flags which do not comply with safety requirements

- Checks should also be made to ensure that the line markings are; straight, in the correct position, the right colour and in line with the laws of the

- Presence of maintenance

- Any other untypical feature of the system

Where a World Rugby Accredited Test Institute deems that there is an issue which may constitute a hazard on the field of play then the manufacturer/World Rugby Preferred Turf Producer/installer shall be required to make safe the issue identified to the satisfaction of the World Rugby Accredited Test Institute, prior to the issue of the Field Test Report to the World Rugby Member Union in whose jurisdiction the field lies.

Note: The shock pad may have been sampled and tested to identify the aforementioned properties at tender stage however it is important that the exposed shock pad is checked when the old carpet is removed prior to the installation of the new turf by an ATI for the issues identified above to ensure it has retained its sports functional characteristics.

8.5 Infill Containment Assessment

All facilities with surfaces installed with intentionally added microplastics (as defined by ECHA), after 01 of January 2022 must ensure that sufficient containment measures have been instigated to prevent, in as much as possible, the migration of performance infill beyond the boundaries of the playing enclosure. This may be as a result of being carried by users, splash from use or maintenance or infill entering drainage systems or other waterways. This aspect shall be assessed using the CEN methods described by CENTR 17519. For clarification purposes, containment is required around the entire sports surface associated with a field, this may, where appropriate include the presence of a non-rugby surface.

8.6 Test Locations

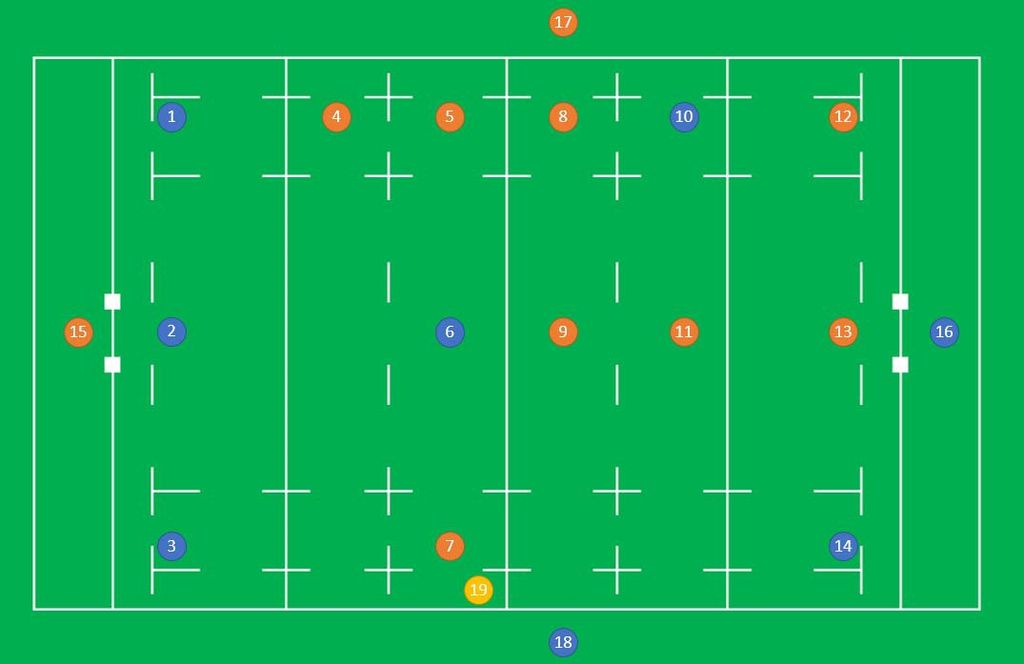

The number of test locations depends on the size of the surface to be tested. For full size rugby fields the image below indicates the test locations to be used:

- All locations indicated must have AAA, infill depth and pile height tests performed

- Blue and yellow marked locations must have Impact Attenuation (HIC), Rotational Resistance and Vertical Ball Rebound tests performed on

- Ball Roll, where required, should be undertaken in six locations chosen by the technician but which give a good indication of the overall condition of the

Locations 17 and 18 should be identified as the most high-use areas adjacent to each of the touchlines.

Note that the location marked in yellow (No.19) is a variable location that should be selected as the location on the Playing Area which is closest to the point of entry of the field. In instances where there are multiple points of entry the most used or the location likely to experience the most wear should be selected.

Any additional areas of concern (for example, sprinkler head or manhole covers) should be tested in addition to the locations indicated in the image above.

The locations indicated in Diagram 8.1 are for reference only. It is permitted to adjust the locations to align with tests undertaken for other sports. The general areas indicated in Diagram 8.1 must be tested even if this means additional locations are to be tested.

Where the total area of the playing enclosure is less than 6,500m2 the number of test locations should be adjusted as follows:

- Less than or equal to 3,000m2 – one third of the equivalent number of test locations for each test

- Between 3,000m2 and 5,000m2 – two thirds of the equivalent number of test locations for each test

- Between 5,000m2 and 6,500m2 – five sixths of the equivalent number of test locations for each test

Where these are not whole numbers the number of test locations must be rounded up to the nearest whole number.

9. Use of Existing Shock Pad Systems and Other Base Types

If an existing artificial turf pitch is converted to an artificial rugby pitch in the refurbishment of an old pitch, there may be existing shock pad systems which can be retained and incorporated into the new pitch. Existing shock pad systems can be retained so long as the following requirements are verified by in-situ testing by an independent laboratory:

- The mean shock absorption of the existing pad is between 90% and 110% of the manufacturers declared shock absorption value when the product was initially submitted for type

- The mean deformation of the existing pad is between 90% and 110% of the manufacturers declared deformation value when the product was initially submitted for type

- The water permeability of the laid shock pad is greater than 500mm/hr when tested in accordance with EN 12616.

- Evenness testing as per EN 13036 with a 3m straight edge should be completed. No undulations greater than or equal to 10mm should be

- No shrinkage gaps greater than 10mm should be present for assembled

- Visually, there is no apparent binder failure or loose friable rubber or significant variance in all

- There is no visible damage to the shock pad, any such areas would require replacement with new

Note: The shock pad may have been sampled and tested to identify the aforementioned properties at tender stage however it is important that the exposed shock pad is checked when the old carpet is removed prior to the installation of the new turf by an ATI for the issues identified above to ensure it has retained its sports functional characteristics.

The installed shock pad shall be tested for each property above in a minimum of 6 positions which provide for a range of usage levels across the field. Tests on the existing shock pad shall be carried out prior to refurbishment, but in any case no longer than 12 months prior to the initial field test, to ensure that the properties of the shock pad do not change in this period. The consistency requirements in place for the field will apply to each of these tests. If the pad has been exposed for any extended length of time then testing should be completed to ensure that UV exposure has not affected the performance. This dispensation does not negate the need for the field to fully meet the Rugby Turf Performance Specification.

10. Field dimensions and markings

The World Rugby Laws of the Game stipulate the required dimensions of the field of play in Law 1 – The Ground (www.worldrugby.org). In cases where there is variation from the World Rugby Laws of the Game and a preferred size cannot be achieved then it will be the responsibility of the World Rugby Member Union to declare a field of play suitable for matches in terms of dimensions.

10.1 Field Dimensions

To be deemed appropriate for hosting international matches the field of play must comply fully with the requirements set down in Law 1 of the Laws of the Game.

These measurements should be taken as follows:

- Field Width is measured from the inside of the touchline to the inside of the opposite touchline

- Field Length excludes the goal line

- The in-goal includes the goal line but excludes the dead ball line

- Carpet size and site dimensions are the dimensions of the entire area covered by rugby In instances where this is not rectangular the shortest dimension should be declared.

Any field which has dimensions smaller than 80m long and/or 55m wide will be considered suitable for training only.

10.2 Field Markings

The field shall be field marked in accordance with Law 1 – The Ground as detailed in the World Rugby Laws of the Game. The line markings and respective competition regulations must be met and checked by the relevant World Rugby Member Union.

All turf used for line markings and any other inlaid designs included on the field must undergo and comply with the same identification tests as the turf used for the main field. On retest, the pile height for these areas must match that of the main field and be checked for fibrillation and/or premature wear of fibres. In cases where substantial fibrillation and or wear has occurred, the field will be deemed to have failed and the sections must be replaced prior to the field being considered compliant. Guidance will be provided to test institutes regarding what constitutes substantial fibrillation and/or wear on the test report document. If there is any doubt about whether substantial fibrillation has occurred World Rugby should be consulted for a decision.

Photographic evidence of the condition of the lines must be provided with every retest and justification for the opinion provided by the tester included.

In instances where lines for other sports are present, these must also comply with the requirements set out above.

11. Maintenance

The maintenance regime provided by the manufacturer must be available for inspection by the accredited technician during field testing. This should include the full package of maintenance training provided, equipment used and the maintenance testing equipment supplied. This equipment should be consistent with the recommendations of the manufacturer.

Following the maintenance practices as issued by the manufacturer/Preferred Turf Producer/installer forms a fundamental part of the care of an artificial turf pitch. Procedures and equipment are prescribed by the manufacturers of the artificial turf system which, if followed, will assist in keeping the field of play in good condition. The most important aspect of these procedures for Rugby is maintaining high performance and ensuring a safe surface for the players. It is essential that properties such as shock absorption are maintained due to the nature of the game which involves contact between players and the surface. Maintenance is crucial to player welfare, the quality of play, longevity of the playing surface and overall aesthetics of the field. Where World Rugby deems that in its opinion an inadequate maintenance regime is recommended, it reserves the right to adjust this regime accordingly.

The manufacturer/World Rugby Preferred Turf Producer’s guidance document will contain specific instructions on how to maintain a pitch and what type of equipment to use. In the context of this document maintenance is referenced to highlight the impact it can have on the safety and performance of a field.

12. Temporary Run-offs

Where a temporary surface is required to extend the run-off areas around a natural turf rugby field, the specification above must be met in its entirety except for the following aspects:

- There is no joint strength requirement in place

- Simulated wear is assessed at 3,000 Cycles

The following restrictions also apply:

- A temporary surface is defined as one which is installed for not more than 65 days per calendar year and not for more than 4 days at a time, unless being used for a tournament not lasting more than 8

- The temporary surface cannot be installed on any part of the playing area, this also includes the touchlines, touch-in-goal lines and dead ball Any artificial surface that is installed as part of any part of the playing area must comply fully with the requirements set out in Sections 1-10 above.

- The temporary surface must have a method of connecting individual sections securely to ensure that the pieces do not separate during The weight of the surface must not be the only factor ensuring that the surface stays in place.

- The installation of the temporary surface should be installed so as to minimise the risk to players when sliding across or treading upon the join between the two

- Where the installation is on a running track, consideration of the presence of varying surface types and obstructions (jumping pits, throwing areas, water hazard, etc.) should be made to ensure that the consistency of performance of the field is met as required within this

- Where the temporary surface is installed on an existing sports surface, performance of this surface must be taken into account when designing the performance of the temporary It is recommended that the temporary surface is tested in the lab, using a sample of the intended sub-surface or something similar in performance prior to installation to ensure compliance will be achieved. The sample should be aged to perform to a similar level as the existing site where relevant.

- Meeting the above restrictions is not in itself validation that the surface will be safe, the venue management must undertake a risk assessment of the solution in situ and act on any issues arising from this assessment.

13. Tables of Requirements

| Property | Test Method | Preparation | Temperature | Condition | Requirements | Variance | |

| Shock Absorption | FIFA Test Method 04a (2016 specification) | Pre-Conditioned | 23°C (±2°C) | Dry | 57%-68% | N/A | |

| Wet | |||||||

| 50°C (±2°C) | Dry | ||||||

| -5°C (±2°C) | Frozen | ||||||

| Simulated Wear | 23°C (±2°C) | Dry | 55%-70% | ||||

On field |

As encountered | ±5%* | |||||

| Energy Restitution |

FIFA Test Method 13 (2016 Specification) |

Pre-Conditioned | 23°C (±2°C) | Dry | 22%-48% | N/A | |

| Wet | |||||||

| 50°C (±2°C) | Dry | ||||||

| -5°C (±2°C) | Frozen | ||||||

| Simulated Wear | 23°C (±2°C) | Dry | 20%-50% | ||||

On field |

As encountered | ±6%* | |||||

| Vertical Deformation | FIFA Test Method 05a (2016 Specification) | Pre-Conditioned | 23°C (±2°C) | Dry | 6-10mm | N/A | |

| Wet | |||||||

| 50°C (±2°C) | Dry | ||||||

| -5°C (±2°C) | Frozen | ||||||

| Simulated Wear | 23°C (±2°C) | Dry | 5.5-11mm | ||||

On field |

As encountered | ±2mm | |||||

| Impact Attenuation (Head Impact Criteria) | World Rugby Test Method 01 or ASTM F3146 | Procedure A | Pre-conditioned | 23°C (±2°C) | Dry | ≥1.3m | N/A |

| Wet | |||||||

| 50°C (±2°C) | Dry | ||||||

| -5°C (±2°C) | Frozen | ||||||

| Simulated Wear | 23°C (±2°C) | Dry | |||||

| Procedure B | On field | As encountered | ≥1.45m | ||||

| Rotational Resistance | FIFA test method 06 (2016 specification) | Pre-conditioned | 23°C (±2°C) | Dry | 32Nm - 43Nm | N/A | |

| Wet | |||||||

| Simulated Wear | Dry | 30Nm-45Nm | |||||

| On Field | As encountered | ±4Nm | |||||

| Vertical Ball Rebound | EN 12235 (expressed as absolute) | Pre-conditioned | 23°C (±2°C) | Dry | 0.6m-1.0m | N/A | |

| Wet | |||||||

| Simulated Wear | Dry | ||||||

| On Field | As encountered | ±0.1m | |||||

* Percentage values for variance should be taken as absolute values

| Property | Test Method | Preparation | Temperature | Condition | Requirements | Variance |

| Angle Ball Rebound | FIFA Method | Pre-conditioned | 23°C (±2°C) | Dry | 45%-70% | N/A |

| Wet | ||||||

| Ball Roll | FIFA Method - Reduced Ball Roll | Simulated Wear | 23°C (±2°C) | Dry | 10m | |

| FIFA Method | On field | As encountered | As required | |||

| Skin/Surface Friction | FIFA Method | Pre-conditioned | 23°C (±2°C) | Dry | 0.35 - 0.75 | |

| Simulated Wear (undressed) | ||||||

| Simulated Wear (undressed) | ||||||

| On field | As encountered | As required | ||||

| Skin Abrasion | FIFA Method |

Pre-conditioned | 23°C (±2°C) | Dry | ±30% | |

| Simulated Wear (undressed) | ||||||

| Simulated Wear (undressed) | ||||||

| On field | As encountered | As required | ||||

| Characteristics | Test Method | Requirement |

| Surface Regularity | FIFA Method |

6mm for impermeable sub-bases 10 mm for permeable sub bases |

| Infill depth | EN1969 | 2 locations are permitted to vary by 5mm from the average |

| Property | Characteristic | Test Method | Requirements | |

| Artificial Turf | Colour Change - Aged | EN ISO 20105-A02 | ≥ Grey Scale 3 | |

| Pile Yarn(s) | Tensile Strength | EN 13864 | Fibrillated | ≥ 30 N |

| Monofilament (per filament) | ≥ 8 N | |||

| Tensile Strength - Aged | ≤ 50 % change from Unaged | |||

| Pile Height | ISO 2549 | ≥ 50 mm | ||

| Polymeric Infill | Colour Change - Aged | EN ISO 20105-A02 | ≥ Grey Scale 3 | |

| Joint Strength (stitched and bonded | Unaged | EN 12228 Method 1 | ≥ 2500N/100mm | |

| After immersion in hot water | EN 13744 & EN 12228 Method 1 | |||

| Joint Strength (Peel - bonded seams only) | Unaged | EN 12228 Method 2 | ≥ 25N/100mm | |

| After immersion in hot water | EN 13744 & EN 12228 Method 2 | |||

| Rugby Strength Direct Tension (both parallel and perpendicular to stitching) | Unaged | ISO 13934-1 | ≥ 25N/mm | |

| After immersion in hot water | ||||

| Shock Pad / E-layers (if supplied) | Tensile Strength | EN 12230 | ≥ 0.15MPa | |

| Product | Water Permeability | FIFA Method | 500 mm/h | |

| Infill splash | FIFA Method | ≤ 3.5% | ||

| Heat | FIFA Method | For information only | ||

| Component | Characteristic | Test Method | Permitted variance from manufacturer's declaration | Testing applies to | ||

| Product | Initial | Retest | ||||

| Rugby Turf | Colour | EN ISO 20105-A02 | As declared | X | X | |

| Mass per unit area | ISO 8543 | ≤ ±10% | X | X | ||

| Tufts per unit area | ISO 1763 | ≤ ±10% | X | X | ||

| Tuft withdrawal force | ISO 4919 | ≥ 40N | X | |||

| Tuft withdrawal force post immersion in hot water | EN 13744 & ISO4919 | X | ||||

| Pile Height | ISO 2549 | ≤ ±5% | X | X | X | |

| Pile Weight | ISO 8543 | ≤ ±10% | X | X | ||

| Yarn (per yarn) | Pile Yarn Characteristics | DSC-ISO 11357-3 | ≤ ±3°C (for all peaks), similar shape | X | X | |

| Pile Thickness | FIFA Method | ≤ ±10% | X | X | ||

| Dtex | See Section 8.2 | ≤ ±10% | X | X | ||

| Shape | FIFA Method | 90% for all dimensions, same shape | X | X | ||

| Performance Infill (If supplied as part of the system) | Layer thickness | EN 1969 | ≤ ±15% | X | X | X |

| Particle Size | EN 933 - Part 1 | ±1 Sieve Size | X | X | X | |

| Particle Shape | EN 14955 | Similar Shape | X | X | X | |

| Bulk Density | EN 1097-3 | ≤ ±15% | X | X | ||

| Composition (% Organic) | TGA | ≤ ±10% | X | X | ||

| Performance Infill (If supplied as part of the system) | Layer thickness | EN 1969 | ≤ ±15% | X | X | X |

| Particle Size | EN 933 - Part 1 | ±1 Sieve Size | X | X | X | |

| Particle Shape | EN 14955 | Similar Shape | X | X | X | |

| Bulk Density | EN 1097-3 | ≤ ±15% | X | X | ||

| Composition (% Organic) | TGA | ≤ ±10% | X | X | ||

| Stabilizing Infill (If supplied as part of the system) | Layer thickness | EN 1969 | ≤ ±15% | X | X | |

| Particle Size | EN 933 - Part 1 | ±1 Sieve Size | X | X | ||

| Particle Shape | EN 14955 | Similar Shape | X | X | ||

| Bulk Density | EN 1097-3 | ≤ ±15% | X | X | ||

| Shock Pad / E-layers (if supplied as part of the system) | Thickness | EN 1969 | ≥ 90% | X | X | |

| Shock Absorption | AAA - FIFA Method | ≤ 5% of the Absolute Force Reduction value | X | X | ||

| Vertical Deformation | ≤ 2mm from declared value | X | X | |||

| Mass per unit area | ISO 8543 | ≤ ±10% from declared value | X | X | ||

| Unbound sub-bases (if tested as part of the system) | Vertical Deformation | ≤ ±10% from declared value | X | |||

| Composition | Same Composition | X | X | |||

| Particle Size Range | EN 933 - Part 1 | ≤ ±20% | X | X | ||

| Particle Shape | EN 14955 | Similar Shape | X | X | ||

14. Provision of Samples

ATIs are responsible for indicating the samples required for testing.

Disclaimer

The World Rugby Rugby Turf Performance Specification has, with the kind permission of FIFA, been reproduced in part from the FIFA Turf Manual

Whilst every effort has been made to ensure the accuracy of the information contained in this document any party who makes use of any part of this document in the construction of an artificial turf pitch (a "User") does so at its own risk and shall indemnify World Rugby their officers, directors, servants, consultants and agents against all claims, proceedings, actions, damages, costs, expenses and any other liabilities for loss or damage to any property, or injury or death to any person that may be made against or incurred by the World Rugby arising out of or in connection with such User's use of this document.

Compliance with the requirements detailed in this document by a User does not of itself confer on that User immunity from legal obligations. Compliance with the requirements detailed in this document by a User constitutes acceptance of the terms of this disclaimer by that User.

World Rugby reserves the right to amend, update or delete sections of this manual at any time as deemed necessary. All rights in the FIFA Turf Manual are reserved to FIFA exclusively. This World Rugby manual may not be reproduced in whole or in part in any manner without the permission of FIFA and World Rugby.