Body Padding Performance Specification

1. Introduction

The use of padded clothing has been prevalent in the sport of rugby since the mid 1990’s. World Rugby, at this time, looked to create a performance specification to ensure that use of these devices was conducted in a manner which did not materially affect the way the game was played. This specification for headgear, shoulder padding and breast padding looked to encourage players to protect themselves rather than providing equipment which would provide additional protection from potential injuries. The only injuries that body padding compliant with this specification are intended to protect against are cuts and abrasions.

This Performance Specification sets out the methods to be used when assessing the performance characteristics required of body padding when used for the sport of rugby union.

The specification also details the minimum requirements for such devices. These requirements shall all be met to qualify the device to carry the World Rugby Approved Mark, as detailed in World Rugby Regulation 12 and the Laws of the Game of Rugby Union.

This Performance Specification does not purport to address all of the safety concerns, if any, associated with its use.

2. Terminology

Body Padding – any device worn on the torso which incorporates padded areas.

As-worn – indicates the way the manufacturer intends a player to wear the device. Except where explicitly required, it shall be assumed that all tests and measurements are completed in this orientation.

Inside-out – indicates the inverse of as-worn, where the internal surface becomes the external surface.

Devices – The assembly of fabrics, pads, labels, and other elements that may go into the construction of padded clothing and are part of the device as intended to be worn by players during a match.

Sample – an individual device submitted for testing.

Padded area – a section of the device that incorporates an impact force attenuating layer in addition to the basic fabric(s) used to hold these layers together.

Hang tag – a tag attached to an article of merchandise giving information about its materials, proper care, and use.

Manufacturer – any entity involved in the manufacture of body padding devices, excluding any entity involved in only constituent parts of a padded clothing device.

Brand – the entity whose name is printed on the device or on the packaging of the device when sold.

Accredited Test House (ATH) – an independent laboratory recognised by World Rugby as being competent to test against the requirements of this Performance Specification. Information on the qualifying criteria for ATHs can be found on the World Rugby website.

g – indicates the acceleration due to gravity at sea level (approximately 9.81 m/s2)

For the avoidance of doubt, any reference to the word “should” within this document indicates that it is recommended but optional for consideration. Any reference to the word “shall” indicates a requirement of this performance specification and a corresponding assessment method will be provided. Where an assessment method is not provided it shall be assessed visually by the ATH

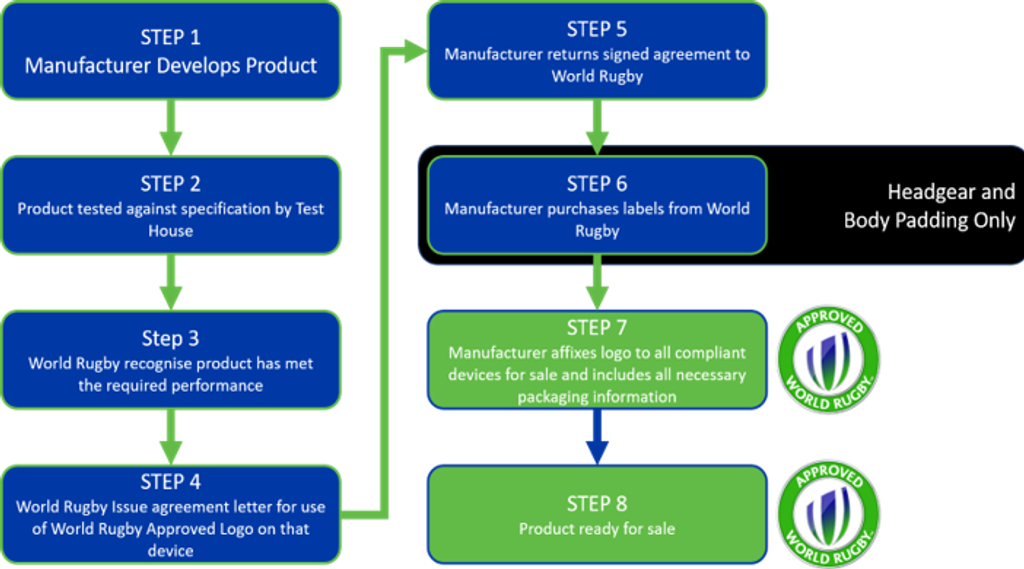

3. The World Rugby Process to Achieve Device Approval

4. Manufacturers

It is the Brand’s responsibility to ensure that any device being sold or supplied for use in rugby has been tested in the laboratory by a recognised ATH to confirm that it meets the requirements set out in this specification.

The brand should consult with an ATH to ensure that the correct components are submitted to enable the assessment to be carried out in accordance with this specification.

Once all testing has been successfully completed, the results shall be submitted to World Rugby by the ATH and an agreement signed by the brand to abide by the conditions of use of the World Rugby Approved Mark.

5. Testing Requirements

All tests related to material properties or performance properties shall be conducted in both the as worn and inside-out orientation in line with the test location requirements.

In the event of any ambiguity arising from the application of these requirements to a specific device, World Rugby reserves the right to decide on the correct interpretation on a case-by-case basis.

5.1 Summary of testing requirements

|

Test |

Conditions | Orientation |

Test Method |

Requirements |

| Thickness | Ambient | - | Calipers | ≤ 12mm |

| Hardness | Ambient |

As worn |

ISO 2349 Method E at 65% compression |

≤ 750N |

| High temperature |

||||

|

Impact Force |

Ambient | As detailed below | ≥ 5kN | |

| Materials | As worn | As detailed below |

||

| Zones of Coverage |

||||

| Finish | - |

6. Design

6.1 Thickness

Body padding including any fabric on each side of the padding shall not exceed an overall thickness of 12mm when uncompressed.

6.2 Zones of Coverage

Using the anatomical definitions in ISO 8559-1, body padding shall not extend beyond the limits set out in Table 2.

| General Description | Location (as per ISO 8559-1) |

| Neckline | Back neck point and side neck point |

| Sleeve | Elbow point |

| Waist | Waist level |

6.3 Ventilation

It is the manufacturer’s responsibility to provide for adequate ventilation in the body padding design.

7. Performance

7.1 Hardness

It is permitted for body padding to be made of distinct layers, but these layers shall be tested in combination as one piece of padding. When tested using the methodology in ISO 2439 Method E at 65% compression in both orientations, the force recorded shall not exceed 750N. The maximum of all forces recorded for all test locations when tested inside-out shall also be within ±75N of the equivalent value when tested as-worn.

The diameter of the platen used when testing to ISO 2439 shall be 60 ±5mm.

Required test locations are described below.

7.2 Impact Force Attenuation

When tested in accordance with the method set out below, as-worn and inside-out, the peak force shall exceed 5kN.

The minimum of all peak force results for all test locations when tested inside-out shall be within ±0.5 kN of the equivalent for as-worn results.

7.3 Retention

Body padding may be secured to the body by a tight-fitting undergarment, where the padding is sewn in or may be inserted into compartments in the undergarment or jersey. Where removable padding is used, each padding section must comply with the requirements of this regulation in full.

Harness type retention systems can be used. Any undergarment should be capable of being attached to the body using adhesive tape or similar where necessary.

8. Construction

8.1 Ergonomics

Body padding should be designed and constructed to minimise discomfort for the wearer. All normal playing movements should not be impeded by wearing the padded clothing.

8.2 Materials

It is the body padding manufacturer’s responsibility that all materials used in the construction of the padded clothing should not be significantly affected by ultra-violet radiation, dirt, perspiration, toiletries, household soaps and detergents. Products should conform to ISO 15487 and ISO 22958.

All materials coming into contact with the wearer’s body should not be of the type known to cause skin disorders and should not cause abrasion of either the wearer or the other players.

Manufacturers should also consider using recycled and or recyclable and environmentally sustainable materials and processes when designing their devices.

8.3 Finish

If distinct layers are used for the padding, the external layers on both sides shall be the same material.

All edges shall be smooth and rounded. In line with Law 4 of the Laws of the Game of Rugby Union, and except where allowed for elsewhere in this performance specification, there shall be no rigid materials that could harm the wearer or other players during normal use.

9. Performance Testing

9.1 Sampling

Three (3) test specimens of one size and two (2) test specimens of all other sizes shall be submitted by manufacturers, complete with ‘information supplied by the manufacturers’ indicated below. One of each size shall be used for as-worn testing and the other for inside-out testing, both at ambient conditions The third specimen of the median size shall be used for as-worn and inside out testing at high temperature conditions.

9.2 Conditioning

Samples shall be stored for at least 4 hours at the required conditions, as detailed in Table 3, prior to testing. If testing is not possible when the device is at the high temperature conditions, then the tests shall be carried out as close as possible to these conditions but not lower than ambient conditions within 5 minutes of removal from the conditioning environment.

| Condition | Ambient | High |

| Temperature (°C) | 20 ±2 | 50 ±2 |

| Relative Humidity (%) | 60 ±5 | |

9.4 Test Locations

All padded areas shall be tested for both hardness and impact attenuation.

The number of tests required in one padded area will depend on the size of the padded area and shall be in line with the explanation in Table 4. The number of test locations required corresponds to the smallest disc size covers the entire padded are. Where a padded area spans across the sagittal plane of the garment then the sagittal plane shall be assumed to dissect the padded area and each side shall be tested as a separate padded area. The face of the test impactor shall never overlap the

edge of the padded area during testing unless it is impossible to avoid this.

When testing at high temperature, only one location shall be tested on the sample in each of the as worn and inside-out orientations. The locations for high temperature conditions shall provide a representative performance for the entire device and be on a different padded area for each orientation unless this is not possible, then the same padded area can be used.

| Disc diameter (mm) |

No. of test locations |

Instructions |

| 150 | 1 | Test location shall be the approximate centre of the padded area. |

| 200 | 2 | Test locations shall be spaced out to give a representative sample of the entire padded area and should overlap as little as possible. |

| 250 | 3 | |

| >250 | 4 |

10. Test Methods

10.1 Impact Force Attenuation Testing

10.1.1 Principle

The test sample is mounted on a cylindrical anvil intended to imitate a human shoulder. A mass with a flat striking surface is dropped onto the padded area in the given location. The peak force and time history of the impact are recorded using appropriate instrumentation. Peak force data are used to determine the impact characteristics of the body padding.

10.1.2 Apparatus

The apparatus for the impact force attenuation test shall consist of the following items (see also, Figure 1).

Figure 1 - Impact Force Attenuation

10.1.3 Drop Assembly

- A steel dropping mass shall be attached to a rail guided drop assembly carriage.

- The mass of 5 ±0.02kg shall be flat and circular with diameter of 130 ±2mm and a 1.0 ±0.5mm radius of curvature at the lower edge.

- The lower, impacting surface of the mass shall be smooth but not polished.

- The mass shall be made of steel with a hardness of at least 55 HRC (Rockwell Hardness Scale C)

10.1.4 Anvil

- The anvil shall consist of a horizontal (±1°) steel cylinder with a diameter of 115 ±2mm and shall not have a resonance frequency liable to affect measurements.

- The anvil shall be made of steel with a hardness of at least 55 HRC

- The centre of mass of the drop mass shall lie approximately over the centre of the anvil

- The anvil shall be mounted on a suitable load cell(s) or force transducer(s) such as a piezoelectric load cell, preloaded according to the manufacturer’s instructions

- The anvil shall be mounted on a heavy rigid block or secured directly to a floor, in a way that does not affect the test results.

10.1.5 Method

Reference Testing

- An MEP (modular elastomer programmer) reference surface with a convex face shall be used, measuring 150 ±2mm in diameter, 25 ±1mm thick at the centre and mounted on a matching steel base.

- The drop mass shall be dropped onto the MEP surface from a distance of 200±5mm.

- Resolved maximum force values recorded on three successive drops shall lie within ±0.5kN of their mean.

Impacting

- The test sample shall be installed on the cylindrical anvil in the intended orientation for the test

- The drop mass shall be dropped from a distance of 200 ±5mm (equivalent to a 9.8J impact).

- When testing multiple locations on the same padded area, allow at least 60 seconds between consecutive impacts.

11. Product Marking

All padded clothing shall be permanently marked with the following information by the

manufacturer and, where relevant, shall comply with the requirements laid out in ISO 8559-2:

- Name and/or trademark of the brand

- Size or size range

- Instructions on how to properly clean and maintain the garment

- Once approval has been secured, a World Rugby Approved Label

- Any additional requirements set out in the territory where the device is for sale.

In addition to the device markings above, once approved, the packaging with which the padded clothing is sold shall include the following information:

- Where the device has external packaging, this packaging must include the messaging below from World Rugby in a format provided by World Rugby to the manufacturer/brand, including any minimum dimensions and resolution prescribed.

- Where the device has hang-tags, an additional tag must be included using the messaging in a format provided by World Rugby. This is in addition to the external packaging requirement above.

Messaging to be included on all World Rugby Approved padded clothing devices:

“This body padding has been designed to reduce the risk of cuts and abrasions to the wearer’s body only, and any impact reduction properties exist solely as a secondary effect of meeting this aim.”

12. Instructional Literature

Devices shall be accompanied by at least the following information:

- Instructions that describe proper use and fit

- Instructions to replace the device after it’s expected useful life

- Instructions on care and maintenance

- Instructions on the recycling and sustainability options available on disposal.

- Warning concerning the improper use of cleaning agents or any other factors affecting the integrity of the equipment.

13. Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this document any party who makes use of any part of this document in the manufacture of rugby headgear (a "User") does so at its own risk and shall indemnify World Rugby their officers, directors, servants, consultants and agents against all claims, proceedings, actions, damages, costs, expenses and any other liabilities for loss or damage to any property, or injury or death to any person that may be made against or incurred by the World Rugby arising out of or in connection with such User's use of this document.

Compliance with the requirements detailed in this document by a User does not of itself confer on that User immunity from legal obligations. Compliance with the requirements detailed in this document by a User constitutes acceptance of the terms of this disclaimer by that User.

World Rugby reserves the right to amend, update or delete sections of this manual at any time as deemed necessary. This World Rugby manual may not be reproduced in whole or in part in any manner without the permission of World Rugby.