Instrumented Mouthguards (iMGs)

1. Introduction

Rugby union is a physically demanding, high-impact sport, which places significant emphasis on player safety and injury prevention1,2. Instrumented mouthguards (iMG) (i.e., mouthguards embedded with sensors) are now commercially available and are used across rugby. Their use provides insight into head acceleration event frequency and magnitude during training and match-play, which holds promise in informing the management of chronic load 3,4. The potential to signal high-magnitude head impact incidents causing possible concussive events, warranting an off-field assessment, serves as a complementary objective measure alongside the current methods of identification by match officials, team doctors, and independent match-day doctors through direct observation and video review.

Recognizing iMGs’ potential for enhancing player safety, and the increase in commercially available products (with varying levels of performance5), World Rugby have developed minimum specification for their use in rugby. These specifications have been developed based on current best practice validity assessments methods, and expert consultation with engineers and biomechanists who are working with and/or have published on head sensors.

Acknowledging the relatively new and evolving nature of the technology, World Rugby commit to reviewing these specifications every six-months to update and refine the specifications concurrently with the technology’s evolution, and ensure transparency as to the limitations of current technology.

This specification sets out the requirements for instrumented mouthguard devices. Instrumented mouthguards are required to meet the specifications relating to impact energy absorption, laboratory and on-field testing to be used at all levels and age grades of the game. Furthermore, instrumented mouthguards intended for use in competitions where the head injury assessment (HIA) process is used are also required to meet the specification for real-time performance. Requirements relating to impact energy absorption, laboratory and on-field testing are specified, with corresponding test methods are described.

2. Terminology

Instrumented Mouthguard (iMG): Mouthguards that have embedded sensors to measure linear and angular kinematics of the head, e.g., linear acceleration and angular velocity.

Personal Protective Equipment (PPE): Specialized clothing, equipment, or gear designed to protect individuals from various hazards, risks, and potential sources of injury or illness in the workplace or other environments. In this instance, it refers to the use of a mouthguard to protect an individual's teeth, gums, and oral cavity from potential injury or damage when playing rugby.

Head Acceleration Event (HAE): the change in speed or velocity of the head as a result of a direct impact to the head or inertial head loading from impact to the body. Head acceleration events can be quantified by instrumented mouthguards.

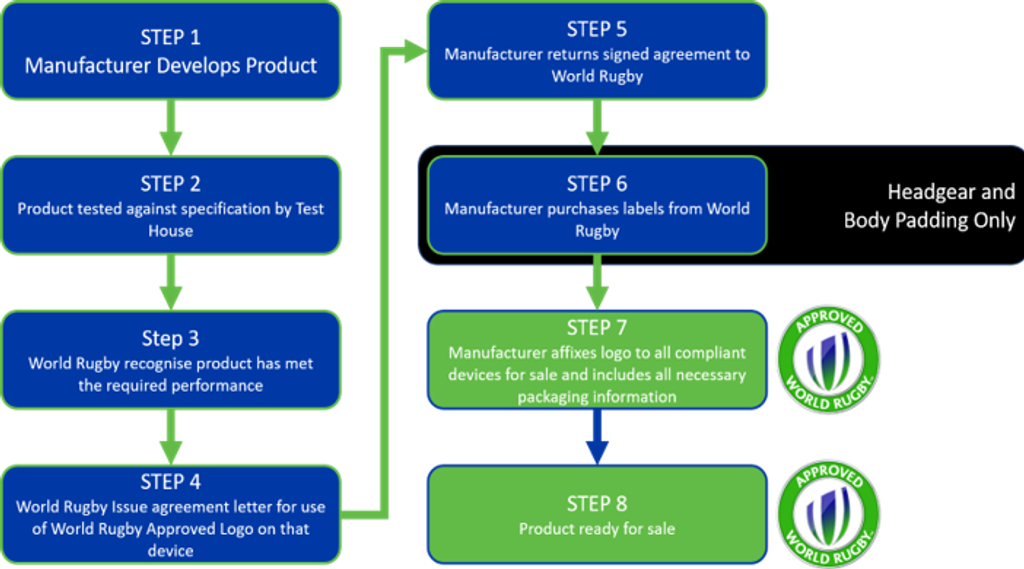

3. The World Rugby Process to Achieve Device Approval

4. Manufacturers

It is the manufacturer’s responsibility to ensure that any product being sold or supplied for use in rugby has been previously tested by a recognized World Rugby Accredited Test Institute to ensure it meets the requirements set out in this specification.

The manufacturer should consult with an Accredited Test Institute to ensure that the correct components are submitted to enable the test to be carried out in accordance with this specification.

The minimum numbers of samples provided for testing must be in compliance with the performance specification.

5. Accredited Test Institute Requirements

To become a World Rugby Accredited Test Institute (ATI) for instrumented mouthguards a test institute must comply with all of the following requirements:

- The Accredited Test Institute shall be wholly independent of any organisation involved in the design, manufacture or sale of any equipment permitted to be used by the Laws of the Game or World Rugby Regulations.

- The Accredited Test Institute shall have the necessary equipment, with valid calibration certificates to complete all tests required in the Performance Specification.

- The Accredited Test Institute has an approved Technician.

ATI accreditation must be renewed, by the signing of a new contract with World Rugby, every 2 years. ATI Accreditation will expire in instances where:

- They cease to be considered independent by World Rugby

- The ATI contract expires and no new contract is signed

- The ATI ceases to have an accredited technician employed/contracted

- The terms of the contract are not met and the contract is terminated

Approved Technician

Technicians are individuals employed or contracted to an ATI that have the required expertise to carry out the performance specification testing. Accreditation is received once the technician is deemed to have the requisite expertise and their ATI has successfully completed the identification element of the process. Once a technician becomes accredited this accreditation will cease to be valid under any of the following circumstances:

- The accreditation is not renewed within 5 years

- The technician’s affiliated test institute is no longer considered an ATI

- A technician becomes affiliated to another ATI

There is no direct cost involved for holding the status of World Rugby Accredited Test Institute and a contract will be required to be signed before any test results will be accepted from applicants.

If you have any further queries or would like to apply to be considered for World Rugby accredited test institute status, please contact the Technical Services Department.

The following test institutes are accredited to test to the Performance Specifications described in this document.

| Performance Specification | Testing House | Approved Technicians |

|

Impact Energy Absorption: CE certification |

Any notified body on the European Commission NANDO database | European Commission NANDO database |

| Laboratory Testing | Virginia Tech University |

Prof. Steve Rowson |

|

On-field Testing Real-time performance |

Leeds Beckett University |

Prof. Ben Jones |

|

On-field Testing Real-time performance |

Ulster University |

Dr. Greg Tierney |

6. Performance Specifications

| Performance Specification | Required performance specification |

|

Impact Energy Absorption |

CE Certification from a notified body. |

|

Laboratory Testing |

Required performance To satisfy the performance specification, at least 80% of measurements must have less than 20% error, iMG measurements must have a proportional bias of 10% or less (slope between 0.90 and 1.10), and a concordance correlation coefficient (CCC) value of 0.90 or higher. To satisfy the required performance specification, this criterion must be met individually for peak linear acceleration, peak rotational acceleration, and peak rotational velocity measurements. Recommended performance It is recommended that manufacturers strive to achieve a performance whereby, at least 86% of measurements have less than 20% error, iMG measurements have proportional bias of 3% or less (slope between 0.97 and 1.03), and a concordance correlation coefficient (CCC) value of 0.96 or higher. To satisfy the recommended performance specification, this criterion must be met individually for peak linear acceleration, peak rotational acceleration, and peak rotational velocity measurements. |

| On-field Testing |

When tested in the field the: - Positive predictive value must be ≥ 90%. |

|

Real-time performance*

*Required for use in competitions where the Head Injury Assessment (HIA) is used.

|

*Required for use in competitions where the Head Injury Assessment (HIA) is used. Required performance As a minimum, iMGs worn in competitions where the HIA is used, must be able to provide data on the number and magnitude of HAE from the first-half or second-half within 5 minutes of the respective half. Data must be within 10% of downloaded postprocessed data, after any inbuilt processing has been applied. Inbuilt processing may take place on-device or in the cloud. In this instance, “real-time” refers to half-time and end-of-match access to the data on the pitch-side device portal. Recommended performance It is recommended that data on the number and magnitude of HAEs can be access within 30seconds of the event. In this instance, after any inbuilt processing has been applied on-device, the data access on the pitch-side portal must be within 10% of downloaded postprocessed data. In this instance, “real-time” refers to instantaneous (within 30seconds) access to the data on the pitch-side device portal. |

6.1 Impact Energy Absorption

Mouthguards are classified as Category 2 personal protective equipment (PPE) in the context of the European Union’s classification system for PPE. As such, World Rugby requires that all instrumented mouthguards, must be CE certified by a notified body to be worn at all levels of the game. The CE marking shows that the manufacturer has ensured that these products meet EU safety, health or environmental requirements. While CE certification allows free movement of products within the European market, it is the manufacturers responsibility to ensure they are compliant with any other PPE legislations required in other geographical areas they intend to sell their product.

The CE marking must be accompanied by the identification number of the notified body. A list of Notified Bodies from each Member State can be found in the European Commission NANDO database.

6.2 Laboratory Testing

Laboratory validation of kinematic measures is required to ensure that HAE data recorded on the iMG are reliable and valid. In-lab testing quantifies measurement error through comparison to reference measurements in dummy headforms that are considered ground truth6.

6.2.1 Equipment set-up

A dummy headform configuration consisting of a medium-sized National Operating Committee on Standards for Athletic Equipment (NOCSAE) headform attached to a Hybrid III 50th percentile male neck, mounted on a linear slide table with 5 degrees-of-freedom must be used.

Reference kinematics are to be measured at the headform centre of gravity with an instrumentation package consisting of three linear accelerometers and a triaxial angular rate sensor.

The iMG must be mounted inside the headform with a detachable three-dimensional (3D) printed detention composed acrylonitrile butadiene styrene plastic. An aluminium plate should be inserted in the space between the iMG and lower jaw of the headform and screwed upward until there is no gap between it and the mouthguard-clad dentition. The plate will act as a clamp to prevent relative motion of the iMG during testing and could be considered to simulate jaw clenching.

A pendulum impactor is used to strike the bare headform. The impacting face of the pendulum is varied to produce varying impact durations. Pendulum impactor faces required for testing include:

- Rigid (nylon, 25 mm thickness)

- Padded (vinyl nitrile foam, VN740 and VN1000)

The hardware, firmware, software, and signal processing of the iMG selected by the manufacturer for laboratory testing must be the same as that used for on-field testing and data collection.

Manufacturers are required to supply three iMG units to the testing laboratory unless instructed differently by the laboratory.

6.2.2 Testing procedure

Two tests must be performed with the pendulum impactor to the bareheaded dummy headform at specified linear acceleration magnitudes (15g, 45g, 75g, 105g, 135g), loading durations (short, medium, long), and impact locations (front, front boss, rear boss, rear) outlined in Table 3.

Peak linear acceleration, peak rotational acceleration, and peak rotational velocity must be recorded at each test.

- Short duration impacts = 2-3ms, rigid nylon impactor face.

- Medium duration impacts = 5-7ms, VN1000 foam pad impactor face.

- Long duration impacts = 10-12ms, VN740 foam pad impactor face.

|

|

Impact Locations |

||||

|

Target |

Duration |

Front |

Front Boss |

Rear Boss |

Rear |

|

15g |

Short |

2 |

2 |

2 |

2 |

|

|

Medium |

2 |

2 |

2 |

2 |

|

|

Long |

2 |

2 |

2 |

2 |

|

|

|

|

|

|

|

|

45g |

Short |

2 |

2 |

2 |

2 |

|

|

Medium |

2 |

2 |

2 |

2 |

|

|

Long |

2 |

2 |

2 |

2 |

|

|

|

|

|

|

|

|

75g |

Short |

2 |

2 |

2 |

2 |

|

|

Medium |

2 |

2 |

2 |

2 |

|

|

Long |

2 |

2 |

2 |

2 |

|

|

|

|

|

|

|

|

105g |

Short |

2 |

2 |

2 |

2 |

|

|

Medium |

2 |

2 |

2 |

2 |

|

|

Long |

2 |

2 |

2 |

2 |

|

|

|

|

|

|

|

|

135g |

Short |

2 |

2 |

2 |

2 |

|

|

Medium |

2 |

2 |

2 |

2 |

|

|

Long |

2 |

2 |

2 |

2 |

6.2.3 Statistical analysis

iMG accuracy for peak linear acceleration, peak rotational acceleration, and peak rotational velocity must be assessed by:

- Proportion (%) of measurements that fall within +/- 20% of the reference kinematic measurements.

- Proportional bias as defined by the slope of an ordinary least product regression between iMG and headform measurements.

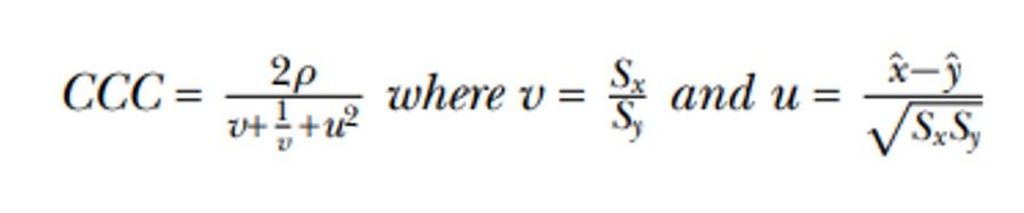

- Concordance correlation coefficient (CCC), where after the sensor and reference measurements are recorded, both are normalised relative to the maximum reference measurement (Equation 1)

(1)

In Equation (1), ρ represents the Pearson correlation coefficient, x and y represent the reference and sensor measurements, respectively. x̂ and ŷ represent the measurement means and Sx and S y represent the measurement standard deviation (SD).

6.2.4 Acceptable performance

Required performance

To satisfy the performance specification, at least 80% of measurements must have less than 20% error, iMG measurements must have a proportional bias of 10% or less (slope between 0.90 and 1.10), and a concordance correlation coefficient (CCC) value of 0.90 or higher. To satisfy the required performance specification, this criterion must be met individually for peak linear acceleration, peak rotational acceleration, and peak rotational velocity measurements.

Recommended performance

It is recommended that manufacturers strive to achieve a performance whereby, at least 86% of measurements have less than 20% error, iMG measurements have proportional bias of 3% or less (slope between 0.97 and 1.03), and a concordance correlation coefficient (CCC) value of 0.96 or higher. To satisfy the recommended performance specification, this criterion must be met individually for peak linear acceleration, peak rotational acceleration, and peak rotational velocity measurements.

6.2.5 Accredited Test Institutes

- Virginia Tech University – Prof. Steve Rowson rowson@vt.edu

6.3 On-Field Testing

On-field testing is required to ensure that the number of head acceleration events (HAEs) recorded during rugby activity are within an acceptable range, and do not contain an unacceptable number of false positive HAEs, or an unacceptable number of HAEs during contact events are missed (i.e., false negatives).

6.3.1 Equipment set-up

The hardware, firmware, software, and signal processing of the iMG selected by the manufacturer for on-field testing must be the same as that used for laboratory testing.

The iMG trigger threshold, that is the criteria for the onset of data acquisition, may be defined by the iMG manufacturer. A combined recording threshold of 8 g (resultant at the head’s centre of gravity) and 400 rad/s2 (resultant) is required to allow representative comparisons before iMG devices.

6.3.2 Testing procedure

Data must be collected from 30 male and 30 female player matches (minimum of 10 mins per match), from either rugby union or rugby league. The 30 player matches must be provided from ≥ 10 unique players. Each player match file must be accompanied with continuous video footage of the player. This includes kick-off to full-time.

Where iMG manufacturers are arranging the collection of this data and subsequently providing it to the testing house for analysis, the matches in which the observations are being collected must be disclosed to the testing house prior to data collection, and the continuous video footage and iMG file provided within 60 minutes of collection. IMG companies will be required to confirm that the processing of HAEs is completed using automated processes and that there is no manual processing between data collection and the provision of iMG data to the testing house.

For each HAE, the following iMG data should be provided to the testing house:

- Both filtered and raw kinematic time series data (SI units).

- Player identifier (name and device number).

- Timestamp to millisecond resolution.

- Peak linear and peak angular acceleration values calculated from the resultant components.

- (If applicable) Outcome of event discrimination algorithms (i.e. true vs false positive algorithms).

- Sensor location and orientation information with respect to the head CG and SAE J211 coordinate system.

6.3.3 Statistical analysis

True-positive events (TP): IMG-triggered events where there is a time-matched HAE (i.e., visible impact to the body or head) with the athlete observed on video.

False-positive active events (FP): IMG-triggered events where the player was on the pitch, but there was no time-matched HAE (i.e., no visible impact to the body or head) with the athlete observed on video.

False-negative events (FN): When a player who was wearing an iMG during a match has a clearly identifiable head impact event (resulting in a visible change in trajectory of the head) but there was no time-matched HAE. True-positives or false-negatives will be based on whether the head impact event timestamp matches the iMG-triggered timestamp and the direction of acceleration is consistent between the video and kinematic time series data of the HAE.

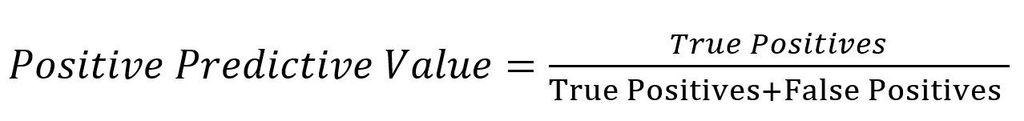

Positive predictive value (PPV) (Equation 2): calculated from the true-positive and false-positive active event counts for each sensor that was field tested and 95% confidence intervals (CI) computed through bootstrapping.

(2)

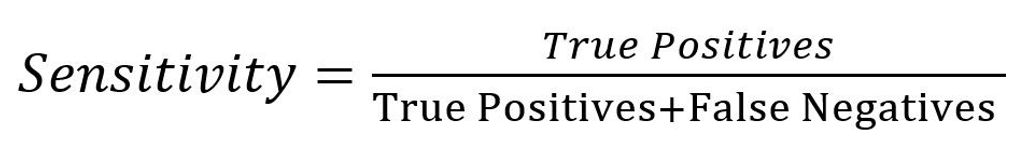

Sensitivity (Equation 3): calculated from the true-positive and false-negatives for each sensor that was field tested.

(3)

6.3.4 Acceptable performance

To satisfy the performance specification, the positive predictive value must be ≥ 90% and field sensitivity (to detect direct head impacts) must be ≥ 80%.

In recognition of the dedication to progress and continuously improve these specifications in tandem with technological advancements, World Rugby strongly recommends that manufacturers include an open disclosure on the positive predictive value and sensitivity of their device. It is recommended that manufacturers use this as a mark of quality and are therefore encouraged to publicise it.

6.3.5 Accredited Test Institutes

- Leeds Beckett University - Prof. Ben Jones jones@leedsbeckett.ac.uk

- Ulster University - Dr Greg Tierney tierney@ulster.ac.uk

6.4 Real-time performance

It is a requirement that iMGs worn in competitions where the Head Injury Assessment (HIA) is used have the functionality to provide data in “real-time”.

Required real-time performance

As a minimum, iMGs worn in competitions where the HIA is used, must be able to provide data on the number and magnitude of HAE from the first-half or second-half within 5 minutes of the respective half. Data must be within 10% of downloaded postprocessed data, after any inbuilt processing has been applied. Inbuilt processing may take place on-device or in the cloud.

In this instance, “real-time” refers to half-time and end-of-match access to the data on the pitch-side device portal.

Recommended real-time performance

It is recommended that data on the number and magnitude of HAEs can be access within 30seconds of the event. In this instance, after any inbuilt processing has been applied on-device, the data access on the pitch-side portal must be within 10% of downloaded postprocessed data.

In this instance, “real-time” refers to instantaneous (within 30seconds) access to the data on the pitch-side device portal.

6.4.1 Accredited Test Institutes

- Leeds Beckett University - Prof. Ben Jones jones@leedsbeckett.ac.uk

- Ulster University - Dr Greg Tierney tierney@ulster.ac.uk

6.5 Approved Devices

|

Approved for use in rugby union |

||

|

Manufacturer |

Model |

Contact |

|

Prevent Biometrics |

Prevent Version 1.4 Custom iMG |

|

|

Prevent Biometrics |

Prevent Version 2.0 Custom iMG |

|

|

HITIQ Ltd |

NEX-MG-1-0004 |

|

|

HITIQ Ltd |

NEX-MG-1-0003 |

|

|

Approved for use in premium-level-HIA matches |

||

|

Manufacturer |

Model |

Contact |

|

Prevent Biometrics |

Prevent Version 1.4 Custom iMG |

|

|

Prevent Biometrics |

Prevent Version 2.0 Custom iMG |

|

7. References

- Raftery, M., Tucker, R. & Falvey, E. C. Getting tough on concussion: How welfare-driven law change may improve player safety- A Rugby Union experience. British Journal of Sports Medicine vol. 55 527–529 Preprint at https://doi.org/10.1136/bjsports-2019-101885 (2021).

- Hendricks, S. et al. ‘Tackling’ rugby safety through a collective approach. British Journal of Sports Medicine vol. 57 562–563 Preprint at https://doi.org/10.1136/bjsports-2023-107020 (2023).

- Tierney, G. et al. Quantifying head acceleration exposure via instrumented mouthguards (iMG): A validity and feasibility study protocol to inform iMG suitability for the TaCKLE project. BMJ Open Sport Exerc Med 7, (2021).

- Tierney, G. Concussion biomechanics, head acceleration exposure and brain injury criteria in sport: a review. Sports Biomechanics Preprint at https://doi.org/10.1080/14763141.2021.2016929 (2021).

- Jones, B. et al. Ready for impact? A validity and feasibility study of instrumented mouthguards (iMGs). Br J Sports Med 56, 1171–1179 (2022).

- King, D. A., Hume, P. A., Gissane, C., Kieser, D. C. & Clark, T. N. Head impact exposure from match participation in women’s rugby league over one season of domestic competition. J Sci Med Sport 21, 139–146 (2018).

8. Contacts

For any enquiry or additional information on Instrumented Mouthguards contact Lindsay.Starling@worldrugby.org